MELTIO

Mold-free production of tailored metal parts Case study developed by Daidore

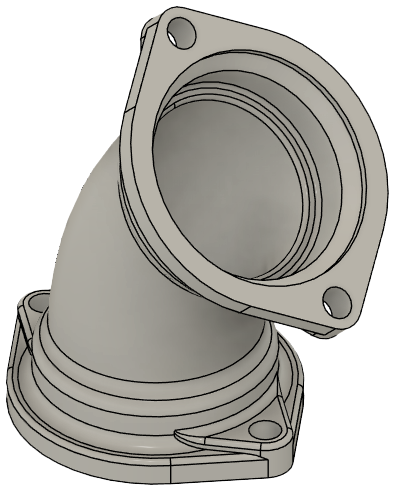

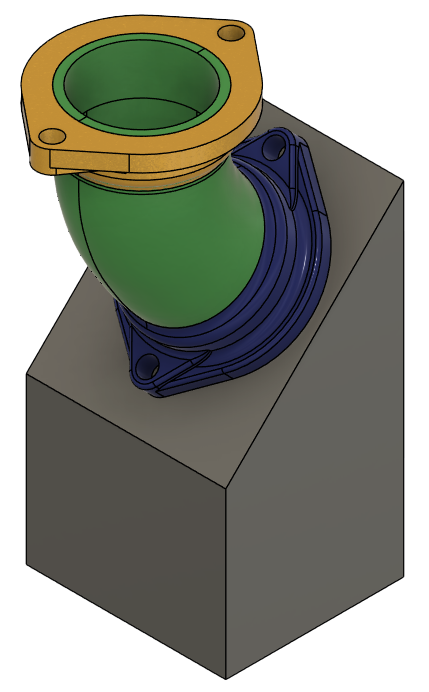

Daidore, a Japanese company for drainage equipment, manholes and other water-related equipment, needed a way to produce a corrosion-resistant pipe elbow for a drainage system, with dimensions that didn’t follow standard fittings. The fitting had to allow for a precise fluid flow path, adapting to a complex pipe layout.

Traditionally, this would mean casting, a time-consuming and rigid process, especially for single or low-volume runs.

Original Source:

https://meltio3d.com/mold-free-production-of-tailored-metal-parts/

The inflexibility of casting

Casting is the go-to method for producing pipe fittings, but it comes with limitations. Once a mold is made, any change to the geometry requires designing and manufacturing a new one.

That’s expensive, slow, and impractical for rapid prototyping or limited runs. This method makes customization a costly endeavor.

Geometry and production freedom

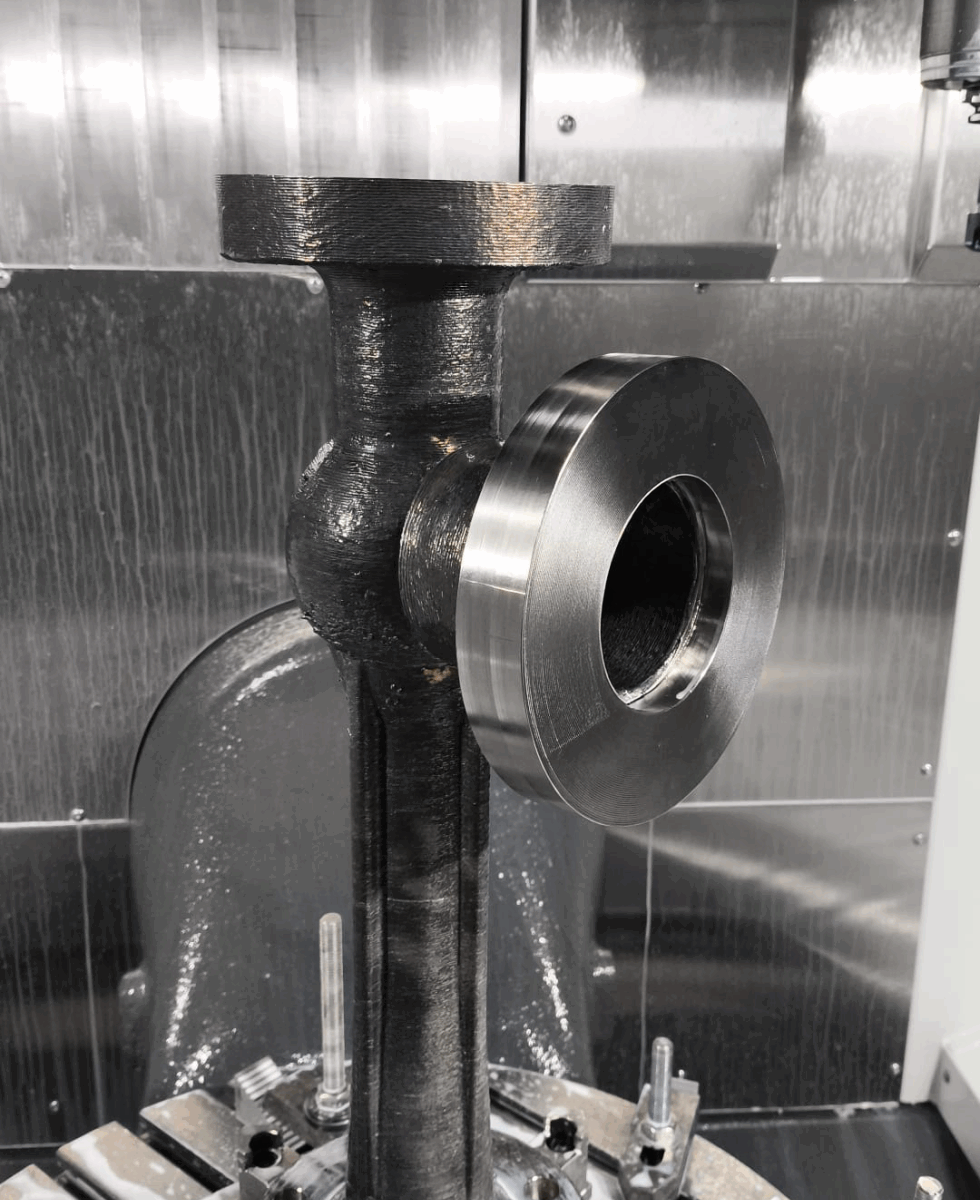

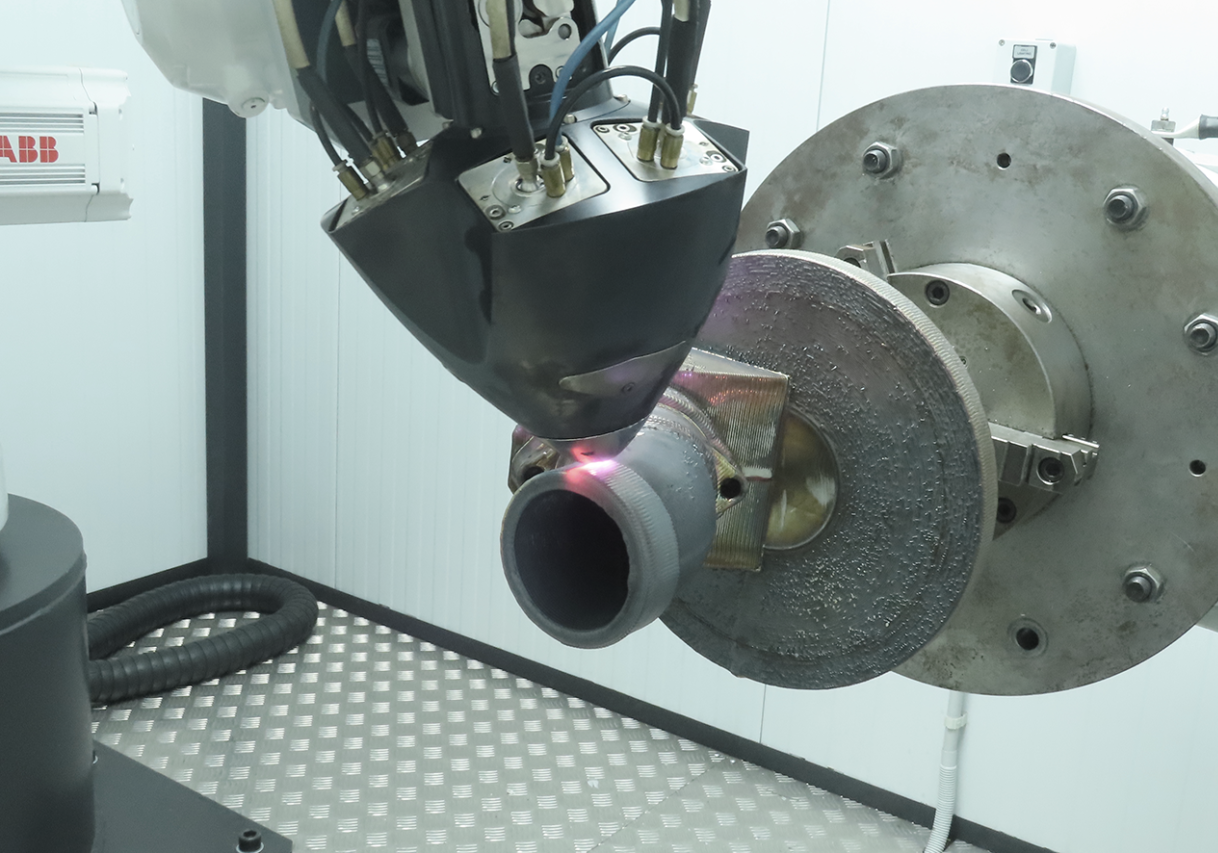

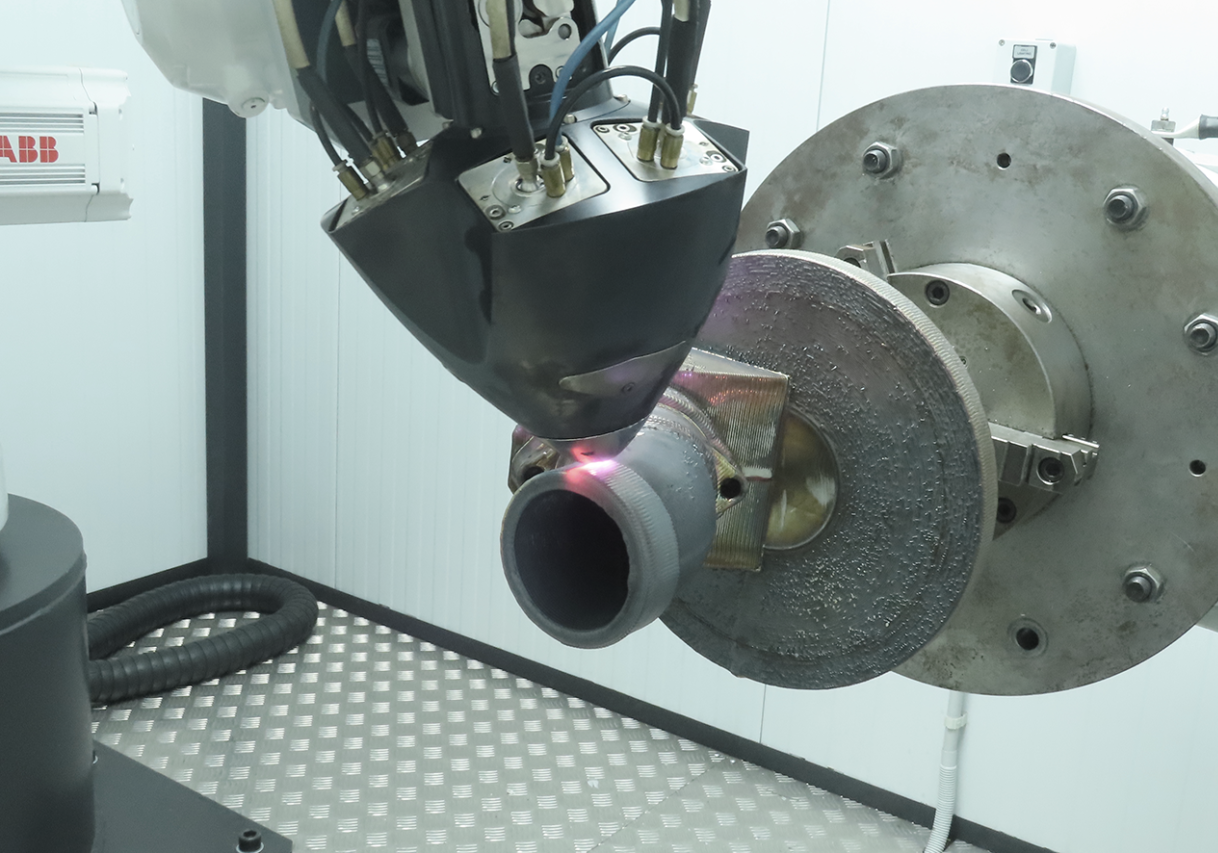

Daidore turned to the Meltio Engine Integration kit for Robotic arms to produce the part using SS316L, a stainless steel known for its corrosion resistance. The component—measuring 165.7 x 107 x 174.7 mm and weighing 3.3 kg—was printed in just under 16 hours with a 1 mm layer height.

Using radial deposition strategies and custom tooling, Meltio’s solution enabled optimal flange orientation without requiring traditional supports.

Built-in efficiency

Thanks to Meltio’s tool-free approach, Daidore didn’t need to design a mold or reconfigure its production line. The part was manufactured lights-out with robotic automation, reducing labor dependency.

The radial printing strategy made the complex geometry not only feasible but reliable, while inert gas usage and energy consumption were kept within tight cost controls.

From casting constraints to additive agility

Daidore’s drainage fitting is a great example of how Meltio’s technology can deliver precision, performance, and customization in metal parts that used to rely heavily on rigid, expensive processes. For industries where time, flexibility, and part integrity matter, this application proves there’s a better way forward.