SOLUKON

Automated depowdering with ultrasonics – Use case justairtech

Original Source:

https://www.solukon.de/en/2025/08/05/automated-depowdering-with-ultrasonics-use-case-justairtech/

Original Content Created by : Solukon

INTRODUCTION

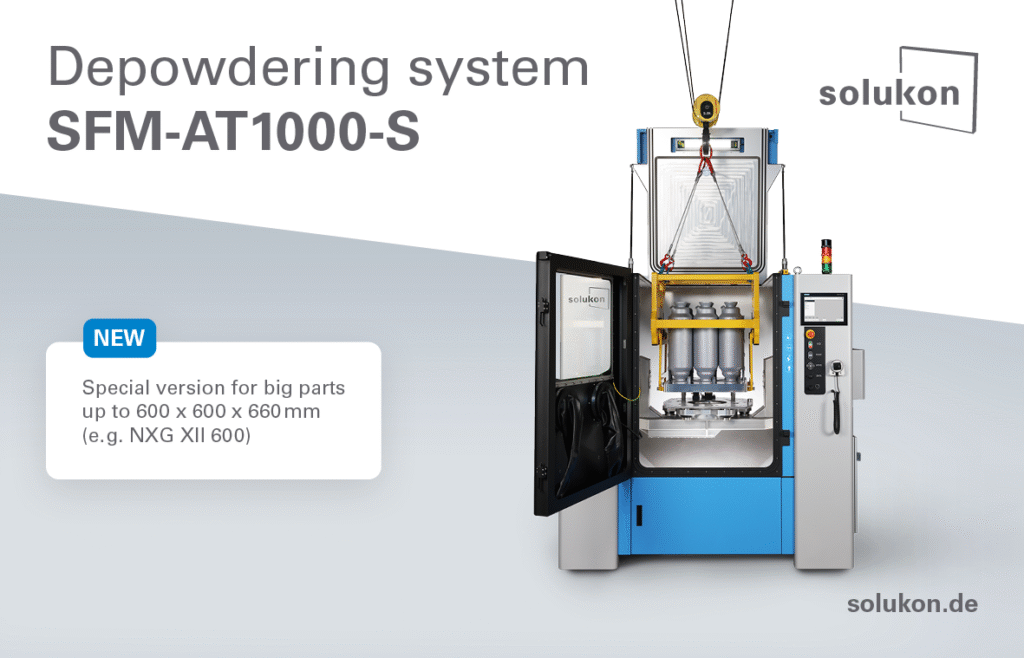

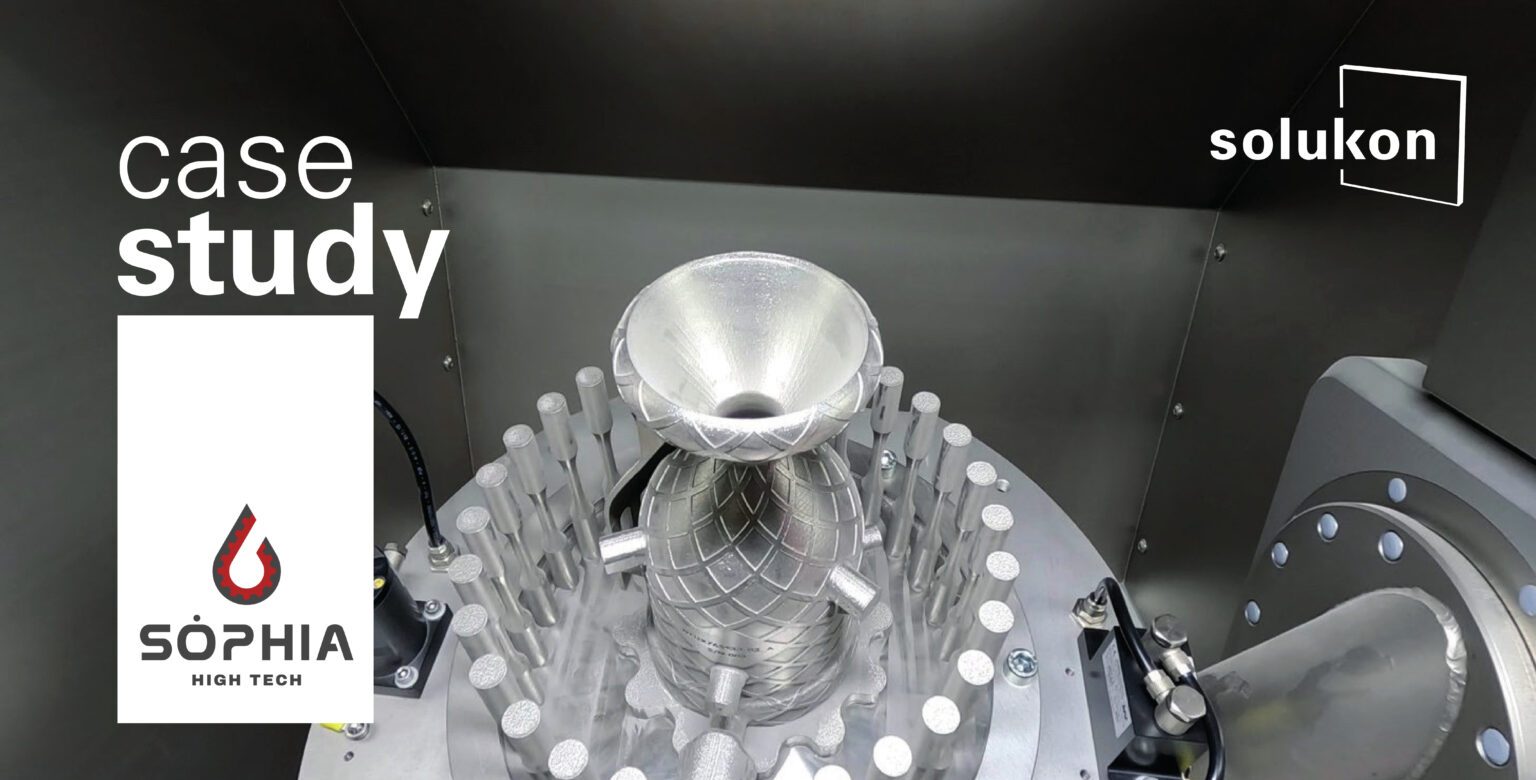

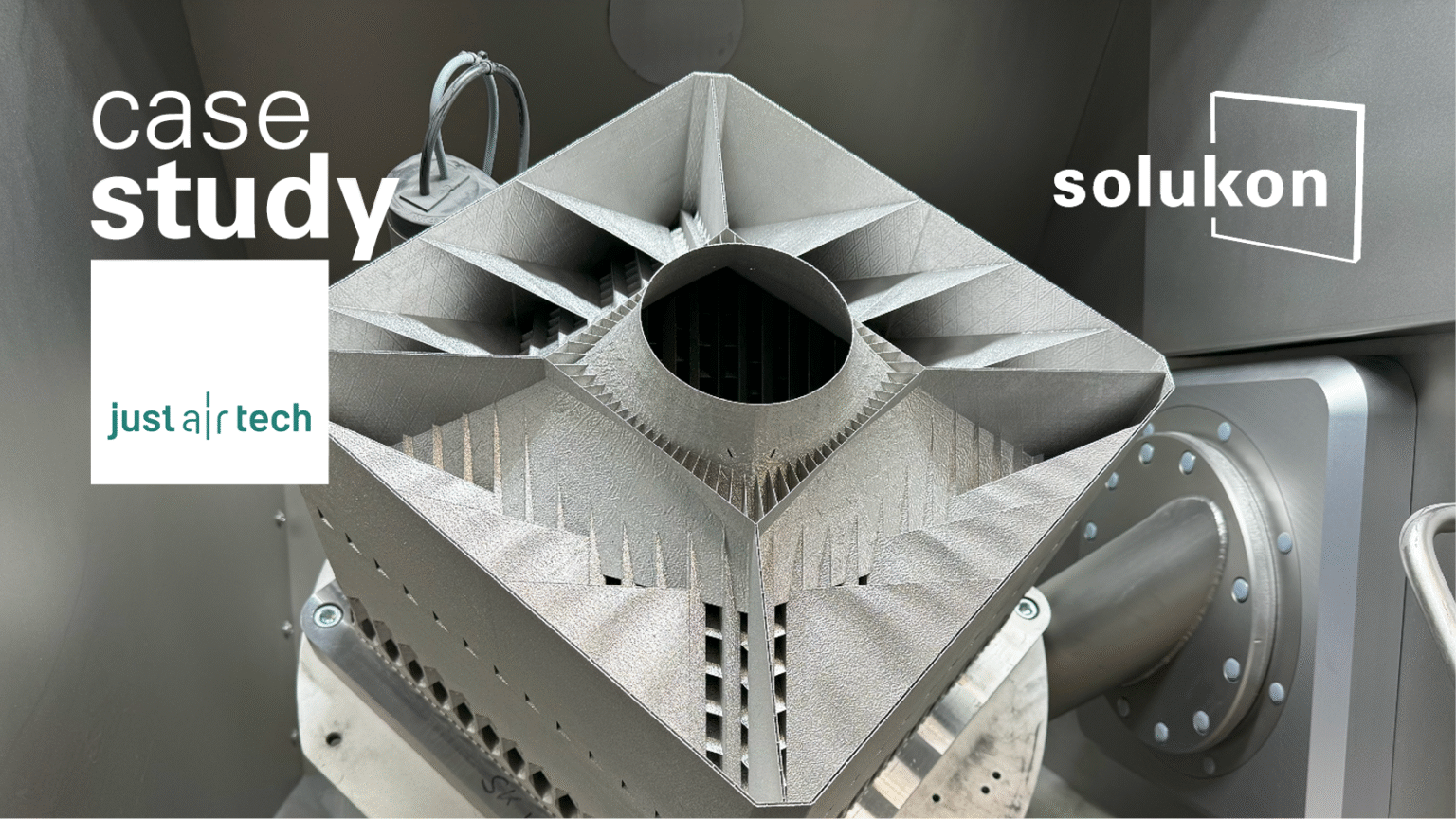

For nearly a decade automated depowdering was widely understood as the combination of automated rotation and targeted vibration. This is still the case but with the launch of the depowdering system SFM-AT350-E Solukon has extended the vibration options with ultrasonic excitation. This case study features the ultrasonic depowdering process of a Fractal Heat Exchanger by justairtech.

The company develops and provides sustainable, highly efficient cooling systems that use air as a refrigerant, primarily targeting data centers and industrial cooling needs. The use case part, their fractal heat exchanger, is their core technology, enabling the use of air as a refrigerant and achieving 4-5 times higher efficiency than conventional systems. They aim to decouple cooling from climate change by reducing electricity consumption and using natural refrigerants.

FACTS & FIGURES ABOUT THE

APPLICATION AND DEPOWDERING PROCESS

| Build plate dimensions (W x D x H) | 350 x 350 x 350 mm |

| Printer with which the part was manufactured | EOS M 400-4 |

| Material | EOS Stainless Steel 316L |

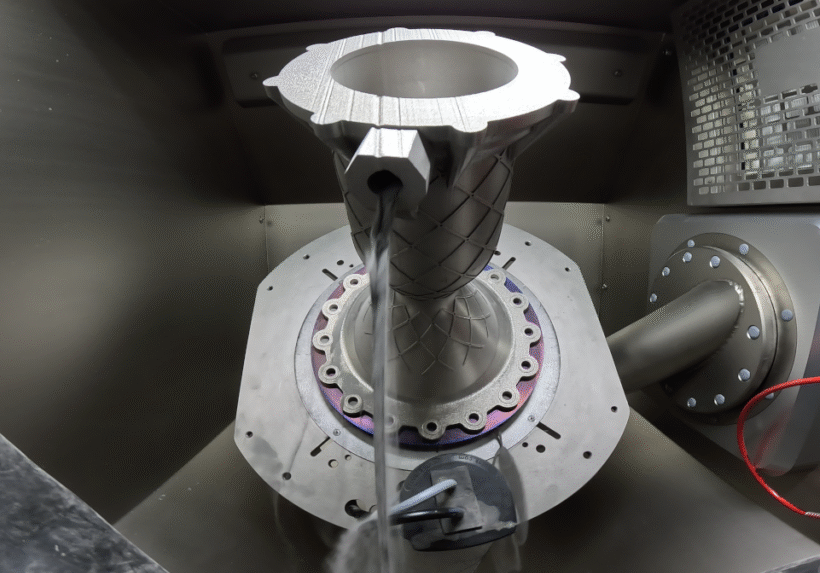

| Application | Fractal Heat Exchanger |

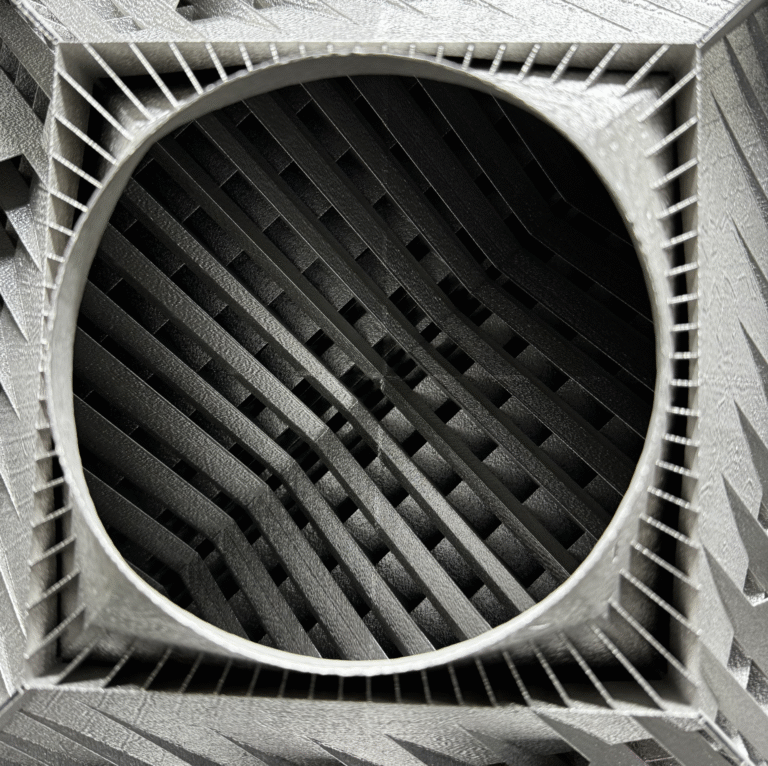

| Structure / surface | – Complex internal geometry with many horizontally running, long and narrow channels; Channel opennings of various geometrical shapes – Spread over the entire base area, approximately halfway up: an area (100 – 150 mm high) in which there is a vertical grid with extremely small gaps (“channels” of 0.5 x 0.5 mm). |

| Smallest diameter of internal feature | 0.5 x 0.5 mm |

| Duration of automatic depowdering | 337 min |

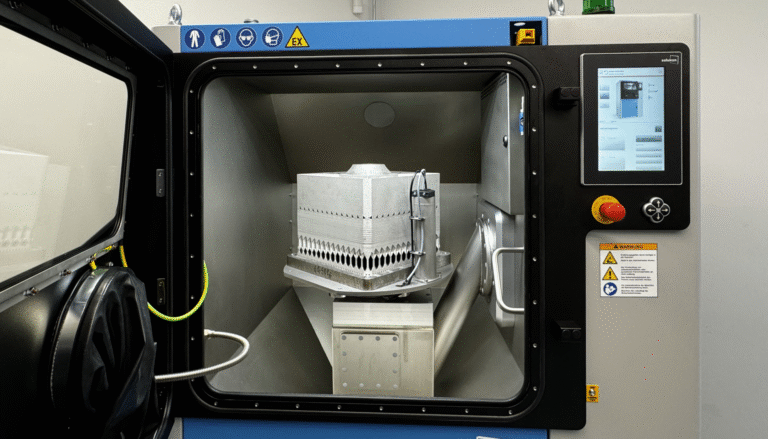

| Depowdering system | Solukon SFM-AT350-E with ultrasonic excitation |

| Mode used | Automatic Mode + Manual Mode |

THE DEPOWDERING PROCESS

Before the ultrasonic depowdering process in the SFM-AT350-E a pre-cleaning has already been conducted. There was a period of time between the first and second cleaning during which the component was exposed to normal room air. It can therefore be assumed that the powder remaining inside the part reacted with moisture from the surrounding air, which further complicated the depowdering process. The depowdering process was carried out on the SFM-AT350-E with permanent ultrasonic excitation and without an option for a pneumatic vibrator or high frequent knocker. During the depowdering also a high impact blasting gun was used to additionally loosen the powder and to get even more powder out of the part. During depowdering in automatic mode (swiveling angle 60°-220°, rotating and swiveling speed 10°/s with waiting times of 5 seconds in each position) a strong powder flow was detected. All in all the ultrasonic depowdering process of this Fractal Heat Exchanger on the Solukon SFM-AT350-E took 337 minutes. Despite pre-cleaning, more than 1.9 kg of stainless steel powder that had attached could be removed. The Heat Exchanger is now completely depowdered.

WHAT IS THE RESULT OF THIS USE CASE?

This use case clearly demonstrates that ultrasonic excitation can make a significant difference when dealing with narrow, long channels. Considerably more powder was removed compared to conventional pre-cleaning using vibration and knocking. Ultrasonic cleaning with the SFM-AT350-E is another powerful tool in Solukon’s comprehensive industrial depowdering toolbox. However, the choice of excitation method still heavily depends on the geometry of the part.

WHAT CONCLUSIONS DOES JUSTAIRTECH DRAW FROM THE POWDER REMOVAL TEST?

The powder removal test impressively confirmed that even powder that gets stuck in component areas that are extremely difficult to access – in our case over 1.9 kg – can be removed automatically. The comparison with the target weight of the heat exchanger shows that the test with Solukon was extremely successful and that the component is now free of powder. This not only provides us with the necessary process reliability, but also strengthens our confidence in the industrial series application of additively manufactured components.”

Philipp Komurka,

Head of Product Development & Technology

Additive Components & Testing

To Download the Full Case Study, please contact casio@hdcinfo.co.kr