ABOUT WAAM

CONTENT CREATED BY MX3D

1. What Is Robotic WAAM?

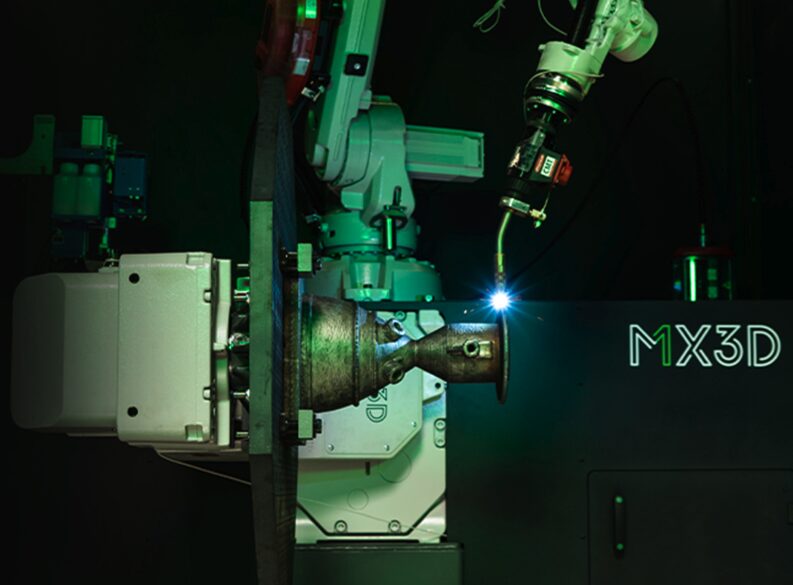

The WAAM (Wire Arc Additive Manufacturing) process melts wire feedstock using an arc heat source to weld or build up material layer by layer. Patented in 1920, it predates the DED (Directed Energy Deposition) process—patented in 1925—by five years. WAAM typically employs conventional welding methods, generating an arc with electrical current to fuse metal. Although similar to LMD (Laser Metal Deposition), WAAM’s thicker wire diameter and inherently less precise weld positioning require more post-processing time than LMD to achieve the final geometry.

ROBOTIC WAAM

WORKFLOW

Robotic WAAM offers a near-net-shape manufacturing process to accelerate the production lead time, reduce machining time, and eliminate up to two-thirds of the production costs.

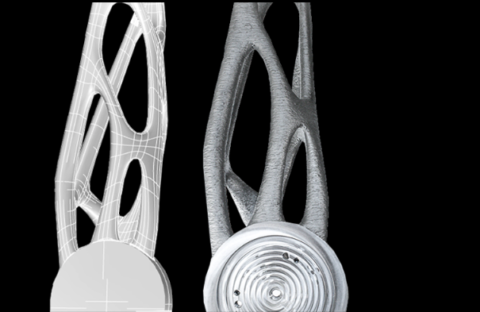

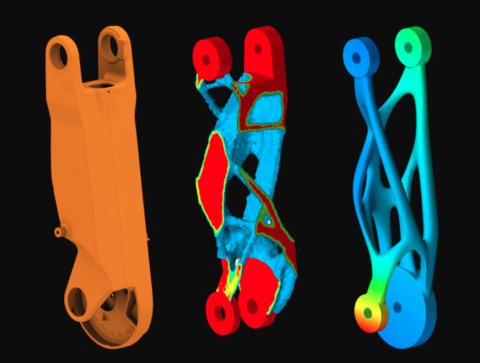

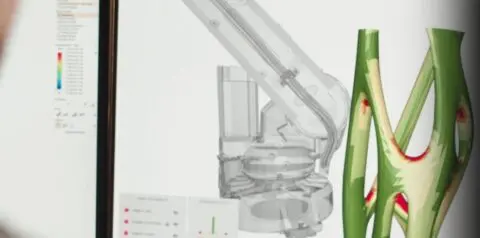

CAD DESIGN

Every digital manufacturing process begins with a digital design (CAD) of the part to be printed.

Robotic WAAM enables topology optimization techniques where weight can be reduced by >50%, resulting in significant manufacturing cost reduction, performance improvement, and increased lifetime value of the part.

TOOLPATH GENERATION

After the CAD has been checked on printability, including wall thickness and overhangs, the toolpath plan can be generated based on parameters and printing strategy and sent to the WAAM system for printing.

PRINTING

WAAM systems operate semi-autonomously in a flexible setup, where the control system monitors key process parameters and warns the operator. The semi-autonomous operation allows WAAM systems to work 24/7 and complete the manufacturing of parts that weigh 100+ kg in a matter of days at a deposition rate of 1-4 kg/hour.

POST-PROCESSING

Different post-processing steps can improve the surface finish and produce the engineered net shape.

CNC machining is the most common and allows the reproduction of features with critical dimensions and tolerances. Grinding or sandblasting is commonly used for large parts with looser dimensional requirements. Optionally, heat treatment relieves the residual stresses to improve the microstructure and mechanical properties of certain materials.

Robotic WAAM Technology

The WAAM (Robotic Wire Arc Additive Manufacturing) system programs a welding robot to produce industrial metal parts by repeatedly melting metal welding wire layer by layer. By combining the concept of metal additive manufacturing with conventional welding wire, it builds complex geometries optimized for industrial use.

WAAM Hardware Configuration

-

Robot-based WAAM: An industrial multi-axis robot deposits metal layer by layer along toolpaths defined in the job file, producing the desired geometry.

-

Industrial Articulated Robot Systems: Highly flexible for a wide range of applications and can be customized to meet the specific requirements of each industry.

-

Enclosed Cartesian Systems: Offer the highest positional accuracy and process control by enclosing the build volume.

-

Add-on Modules: Convert existing equipment into hybrid systems that combine additive layering with subtractive machining.

Control System

The WAAM control software orchestrates every step of the process to ensure that parts are manufactured exactly as intended. A robust control system is at the heart of WAAM because it:

-

Generates Toolpaths

Translates the job file into machine instructions and metal-additive deposition strategies. -

Executes Robot Motion

Converts all programming into precise physical movements. -

Monitors Quality

Uses sensors to guarantee safe operation and high-quality WAAM output.

Welding Process Control

In principle, any welding method can be used with WAAM. In practice, three processes are most common:

-

MIG (GMAW): Offers the highest deposition rates for large parts in open environments; easy to implement with low equipment costs.

-

CMT: A variant of MIG with lower heat input and tighter process control, reducing thermal distortion.

-

TIG (GTAW): Provides superior weld quality at lower speeds but requires a rotating wire-feed mechanism.

Use of International-Standard Welding Wires

Standard wires such as stainless steel, aluminum, copper alloys, high-strength steels, and Inconel can all be used. By integrating MetalXL software with an industrial robot, you can manage the entire workflow—from part design to printing—in a single, streamlined interface. As a result, WAAM finds applications not only in traditional industrial sectors but also in the design and creative industries.

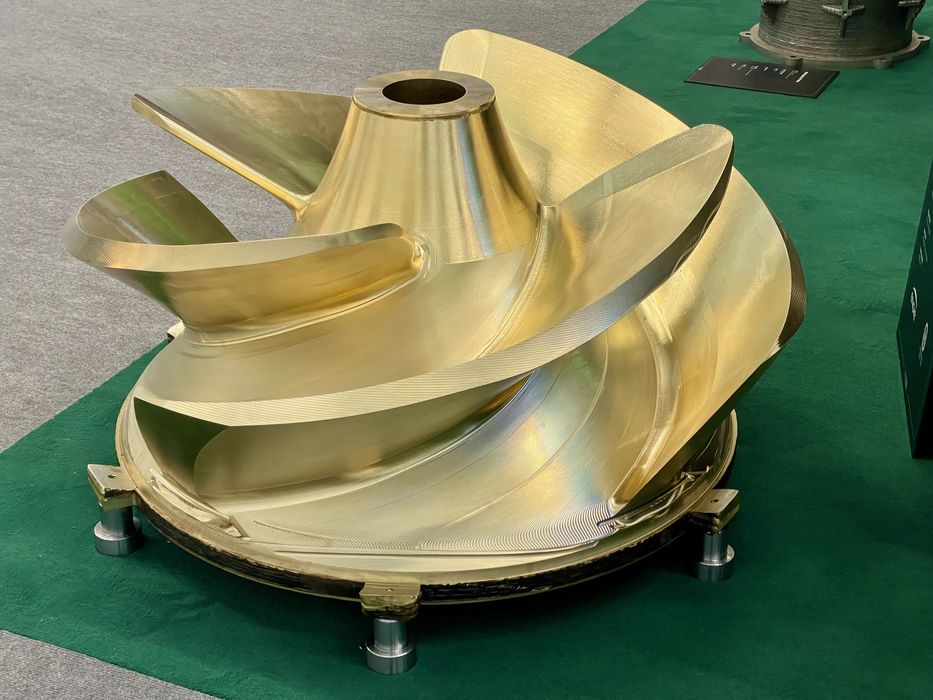

Ideal for Marine and Large-Part Production

MX3D’s robotic WAAM excels at fabricating complex, large-scale components for the shipbuilding and offshore sectors. Instead of stocking spare parts, operators can rapidly produce replacements on-demand—minimizing downtime and eliminating the need for extensive spare-parts warehouses. With MX3D equipment, large impellers, propeller blades, aluminum keels, cowling vents, and more are manufactured reliably.