ABOUT LFAM

Large-Format Additive Manufacturing with Composite & Plastic Pellets

1. What Is LFAM?

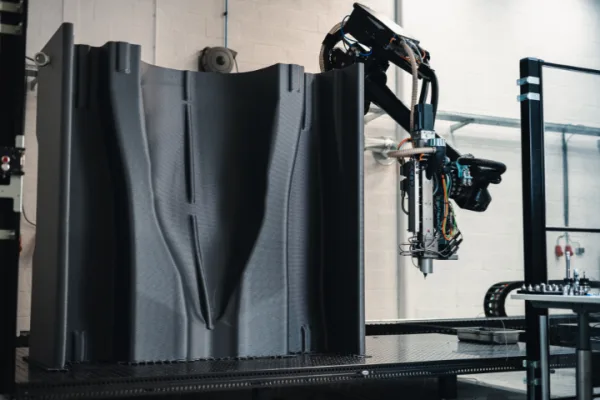

Large-Format Additive Manufacturing (LFAM) is the process of 3D printing very big parts—often meters in size—using pelletized thermoplastics or composite materials. Unlike traditional filament- or powder-based 3D printing, LFAM systems feed granules through a high-throughput extruder, enabling faster build speeds and lower material costs.

Why Pellet-Based 3D Printing?

Cost Efficiency:

Pellets cost up to 70% less than equivalent filament.

High Throughput:

Continuous feeding allows sustained deposition rates ≥10 kg/h.

Material Variety:

Wide range of engineering plastics and composites (PETG, ABS, PA, PP, PC, etc.).

Easy Recycling:

Regrind scrap parts directly into future builds.

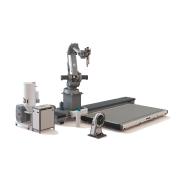

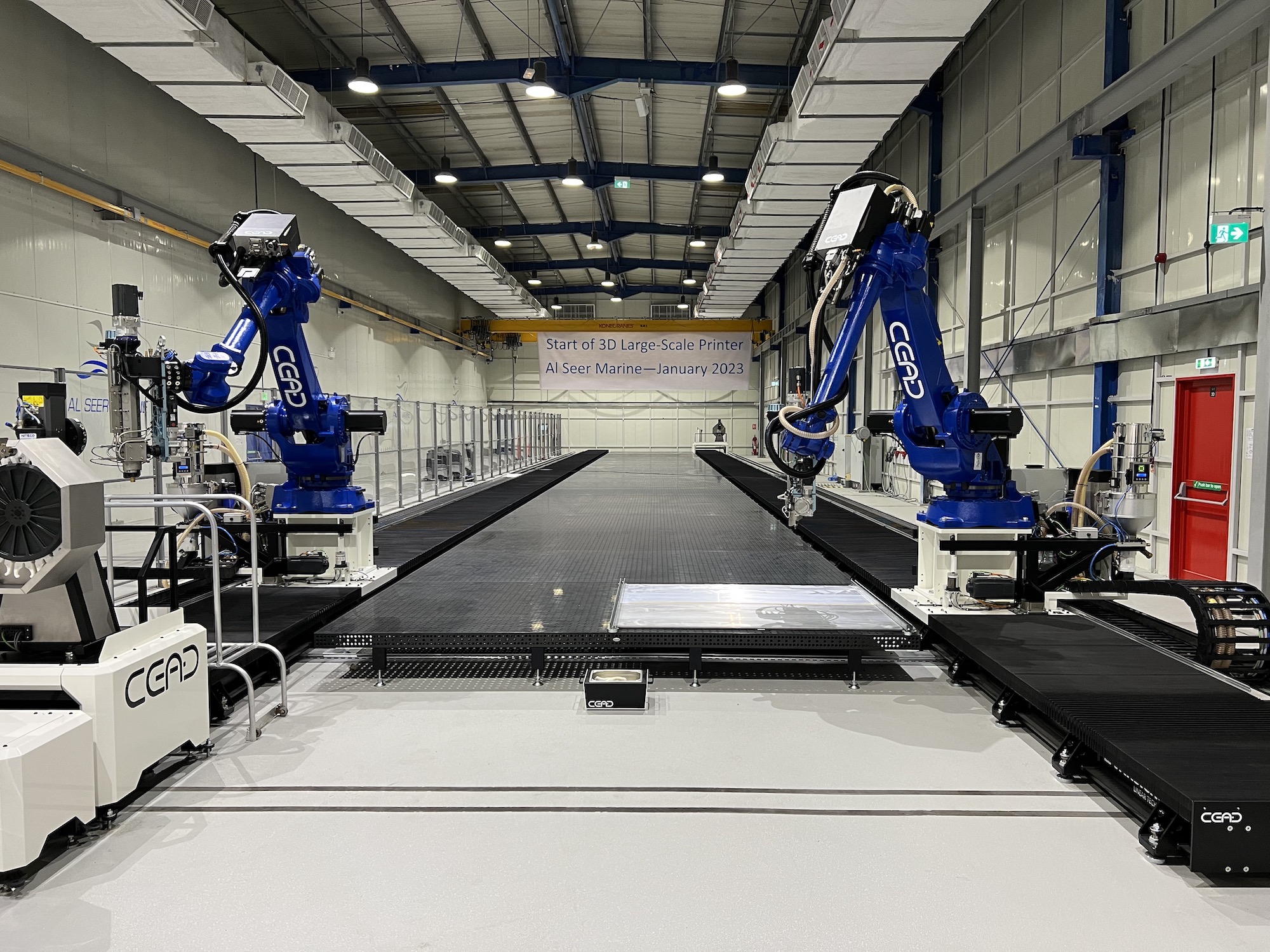

© Flexbot custom set-up at Al Seer Marine

How Does It Work?

1. Pellet Hopper: Load your selected polymer or composite pellet into the hopper.

2. High-Torque Extruder: A geared motor and screw convert pellets to molten filament.

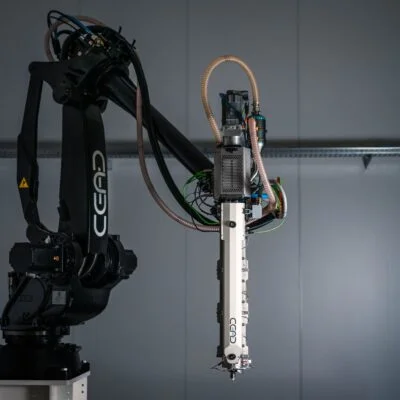

3. Large-Format Gantry or Robotic Arm: Deposits molten material layer by layer to build big parts.

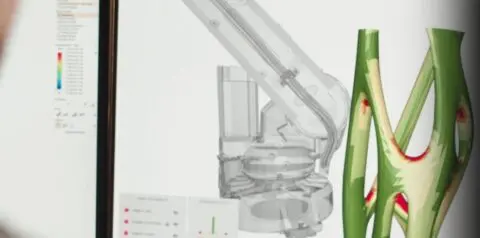

4. Optional Reinforcement: Integrate continuous fibers (carbon, glass) for extra stiffness in critical areas.

LFAM excels wherever you need large, strong, lightweight parts:

• Aerospace fairings & tooling

• Automotive prototypes & jigs

• Marine hulls & deck components

• Architectural models & formwork

• Industrial tooling & end-use parts

Why Choose CEAD?

CEAD is a world leader in pellet-based LFAM, trusted by engineers across aerospace, marine, automotive and architecture. Here’s what sets CEAD apart:

• Modular Platforms: Quickly adapt build volume from 1 × 1 m up to 3 × 2 m.

• Durable Pellet Extruder Heads: Switch between pure plastics and/or composite blends on the fly.

• Integrated Fiber Reinforcement: Co-extrude continuous fibers for >50% stiffness boost.

• User-Friendly Software: CEAD’s intuitive slicer handles large assemblies and multi-material prints.

• Global Support: On-site commissioning and 24/7 remote assistance in Asia, Europe, and North America.

TOOLPATH GENERATION

After the CAD has been checked on printability, including wall thickness and overhangs, the toolpath plan can be generated based on parameters and printing strategy and sent to the WAAM system for printing.