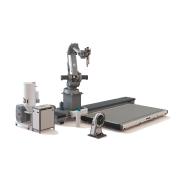

THE WORLD’S BEST-SELLING DEPOWDERING SYSTEM

The SFM-AT800-S is a precision-engineered automated depowdering system designed for complex metal components up to 600 mm in height. This advanced solution delivers fully automated, highly efficient powder removal — reaching deep into internal channels and intricate geometries. With programmable, unlimited dual-axis rotation and integrated vibration within a sealed, controlled atmosphere, it ensures thorough cleaning for even the most demanding additive manufacturing applications.

INTELLIGENT DEPOWDERING

WITHOUT PROGRAMMING

The SFM-AT800-S is compatible with SPR-Pathfinder® software with serial number 1 and above. For each build job, SPR-Pathfinder® uses the CAD file to calculate the individual motion pattern, which the SFM-AT800-S then follows to remove all the powder.

SAFETY AND CONNECTIVITY

After the cleaning process, you manually can depowder any residual powder manually via sealed glove ports by using inert gas or compressed air. When you depowder reactive materials such as aluminum or titanium, the system can be inerted. The recovered metal powder can be reused and is available for other build jobs.

In addition, the SFM-AT800-S has an OPC UA interface and can be loaded by robot.

INTELLIGENT DEPOWDERING

WITHOUT PROGRAMMING

Fully compatible with SPR-Pathfinder® software (serial number 1 and above), the SFM-AT800-S automatically generates optimized motion paths from CAD data for each build job. This ensures complete powder removal, even from complex internal geometries — without the need for manual programming.

SFM-AT800-S PRODUCT DETAILS

- Automated, unlimited 2-axis swivel device

- Material lock with special container for collecting metal powder

- Vibrator with a wide frequency range

- Manual depowdering (with compressed air or inert gas) of residual powder via sealed glove ports

- Manual control by joystick

- Powerful dust removal for non-reactive materials

- Protective gas inertization for reactive materials in accordance with ATEX

- SPR-Pathfinder® Software for simulating and programming the cleaning program

- Programmable knocker

- Direct connection to a recycling unit

- Top loading

- Digital-Factory-Tool

- OPC UA interface (Industry 4.0 ready)

| TECHNICAL DATA | |

|---|---|

| Machine dimensions (W x D x H) | 2,140 x 1,370 x 2,160 mm |

| Installation space (W x D x H) | 3,500 x 2,500 x 3,000 mm |

| Weight | 1,100 kg |

| Supply voltage / frequency | 400 / 50 – 60 V/Hz |

| Power consumption | 1.5 kW |

| Power connection | 16 A |

| PART | |

|---|---|

| Weight | max. 300 kg |

| Dimensions | up to 600 x 600 x 600 mm or 800 x 400 x 550 mm |