CEAD –LARGE SCALE ADDITIVE MANUFACTURING 3D PRINTING REINVENTED!

Innovating the Future of Industrial Manufacturing

CEAD is a global leader in large-scale composite additive manufacturing. Based in the Netherlands, CEAD designs and builds advanced 3D printing systems capable of producing strong, lightweight parts using thermoplastic pellets and continuous fiber reinforcement. These solutions are ideal for demanding applications across industries such as aerospace, maritime, automotive, construction, art and energy.

NUMBER OF COUNTRIES INSTALLED

NUMBERS OF MACHINE INSTALLED GLOBALLY

COMPANY FOUNDED

PARTNERS

WHY CEAD?

CEAD is a global leader in large-scale composite 3D printing solutions, delivering powerful technology for manufacturing strong, lightweight, and customized parts at industrial scale. Their innovative systems combine pellet-based extrusion with continuous fiber reinforcement, giving manufacturers the freedom to build large structures with structural integrity and speed — all with sustainable, high-performance thermoplastics.

Whether you need tooling, prototypes, functional parts, or full-scale production, CEAD offers flexible, modular, and robot-integrated systems to suit your needs.

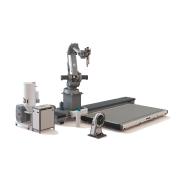

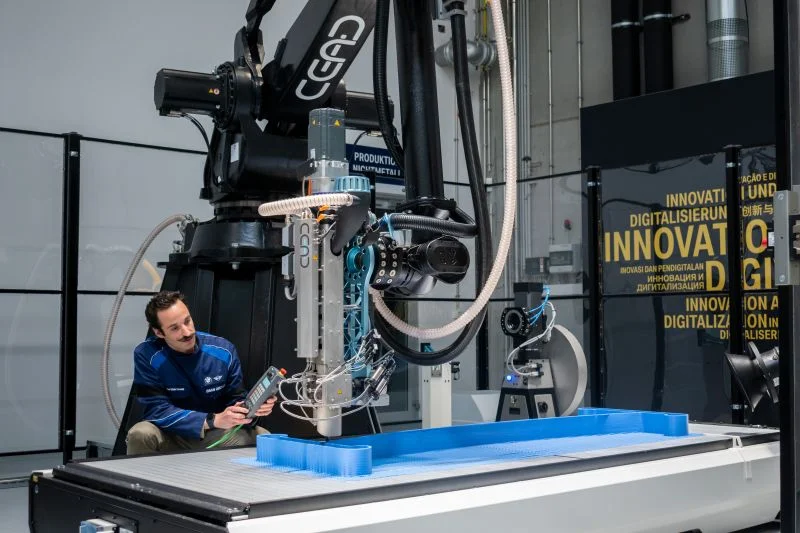

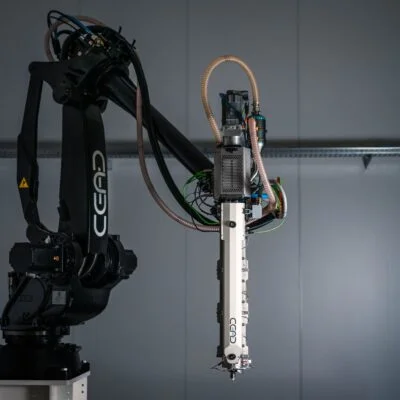

The Flexbot is a versatile robotic solution designed for large-scale additive manufacturing. It offers both standard and custom configurations — from 3D printing entire boat hulls to seamlessly integrating subtractive manufacturing techniques.

Designed for both high performance and ease of use, the Flexcube delivers powerful capabilities within a compact footprint. Integrated milling and finishing options enable seamless part completion without the need for removal from the machine.

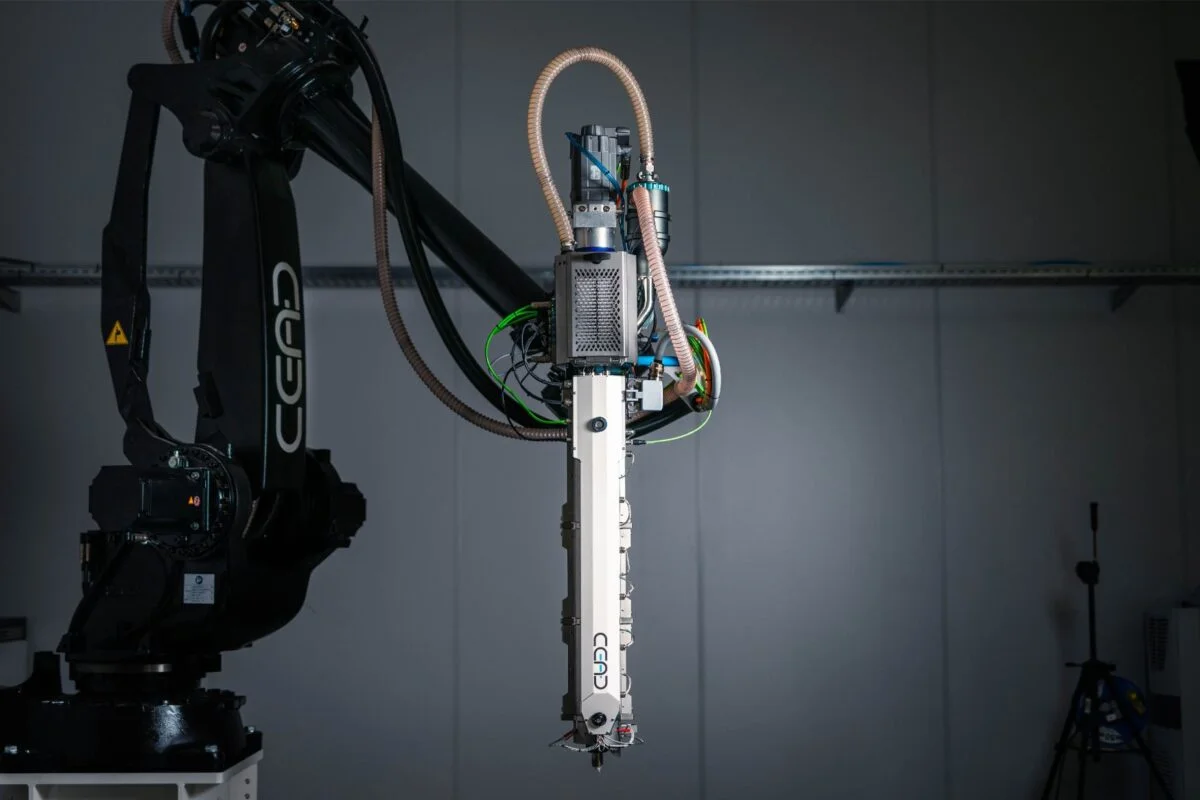

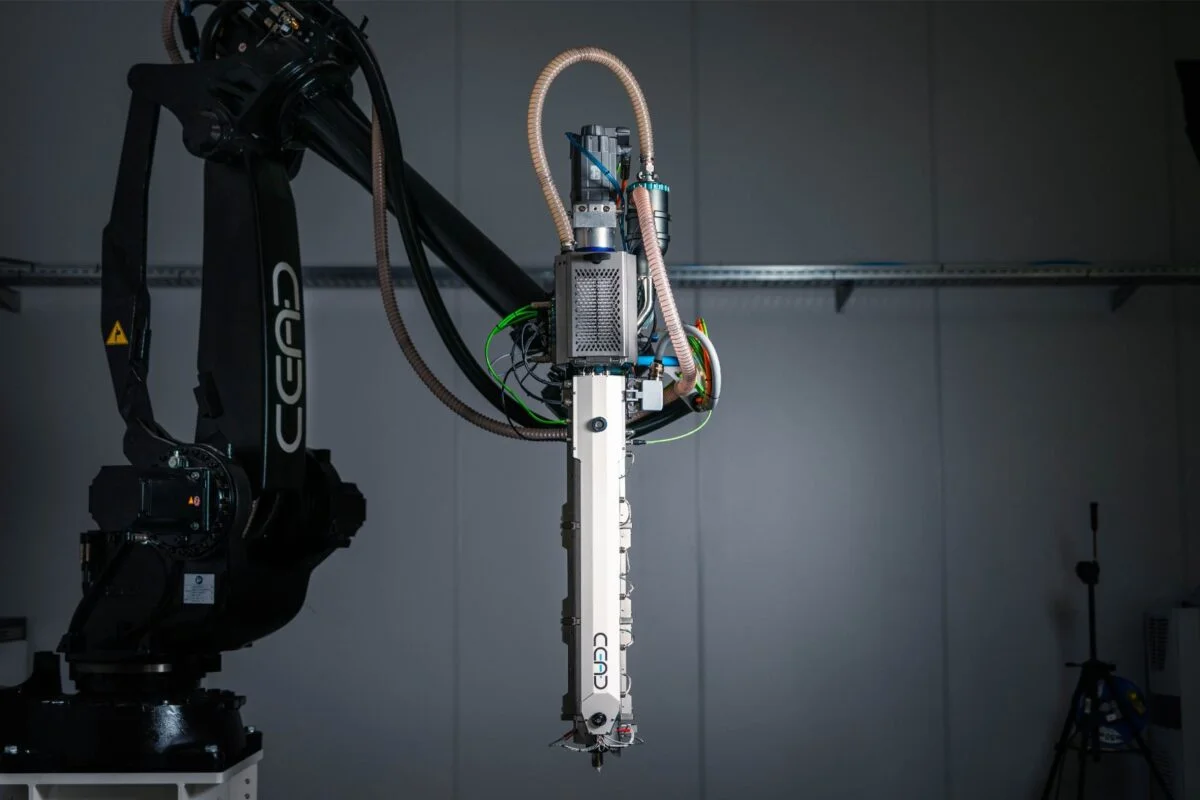

Pellet extruders are stand alone build for integrators and companies alike. CEAD offers its robot pellet extruders as separate technology components that can be used to build modular large scale 3D printers.

AREAS CEAD IS WELL USED

LOVED BY THE INDUSTRY

The CEAD AM Flexbot is a turnkey solution that combines a high-performance printhead with a multi-axis industrial robot. It offers unmatched flexibility in printing orientation and size, with optional CNC milling integration for post-processing.

PELLET EXTRUDER SPECIFICATION

E25 Pellet Extruder

Weight: 30 kg

Max output: 12 kg/h

Nozzle size: 2-18 mm

S25 Pellet Extruder

Weight: 40 kg

Max output: 24 kg/h

Nozzle size: 2-18 mm

E40 Pellet Extruder

Weight: 70 kg

Max output: 60 kg/h

Nozzle size: 4-24 mm

E50 Pellet Extruder

Weight: 170 kg

Max output: 84 kg/h

Nozzle size: 4-24 mm

SCAN2MIL

This feature, integrated in AdaOne for Flexbot (collaboration with ADAXIS), streamlines post-3D printing processes by automatically creating a milling path based on collected data

CUSTOMER USE CASES:

CUSTOMER INQUIRIES

PLEASE FEEL FREE TO INQUIRE ABOUT ANY ADDITIONAL QUESTIONS YOU HAVE REGARDING ROBOTICS 3D PRINTING OR METAL POWDER REMOVAL.