MELTIO-AFFORDABLE WIRE LASER DED TECHNOLOGY

Meltio is redefining metal 3D printing with its proprietary wire-laser deposition technology, offering a compact, cost-effective solution for producing fully dense, industrial-grade metal parts. Unlike powder-based systems, Meltio uses standard welding wire — making it safe, clean, and easy to adopt in any workshop or factory.

Whether you're building new components or repairing existing ones, Meltio enables reliable metal printing in a standalone unit or integrated directly onto CNC machines and robotic arms.

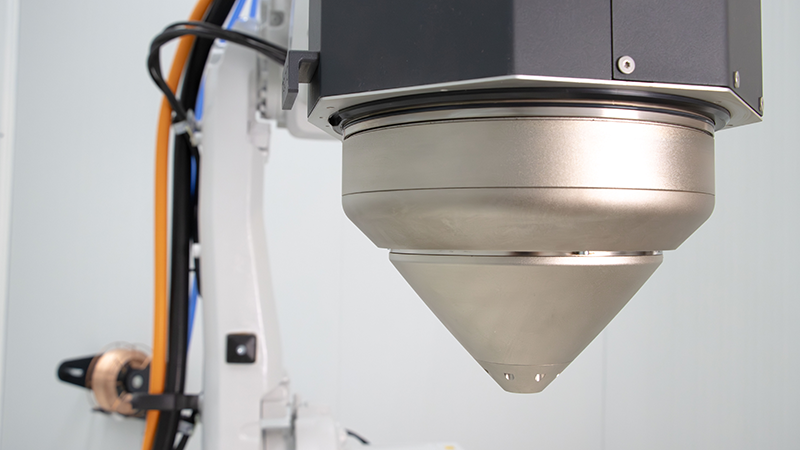

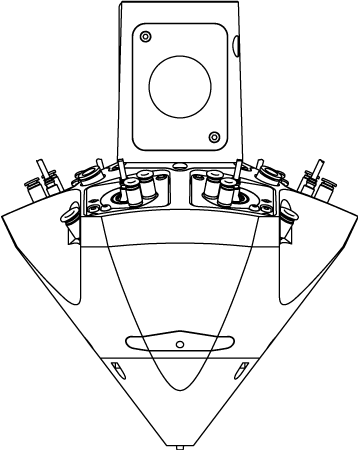

MULTI-LASER BLUE DEPOSITION HEAD

Enhance performance and reliability

Augmented energy delivery efficiency reduces energy consumption, making it a cost-saving process, thanks to the blue laser diodes

Blue Light

450 nm light improves energy absorption and printing efficiency across the metal material spectrum.

No Calibration

It arrives aligned from the factory for maximum printing repeatability and minimal maintenance.

Hotwire Compatible

The deposition head is developed to used with an optional hotwire supply to increase the deposition rate and allow for more materials to be processed.

High Efficiency

The energy consumption per component is reduced significantly, resulting in a greener and more cost-efficient process.

MULTI-LASER IR DEPOSITION HEAD

Make accesible repair works

It comes packaged in a compact deposition head, a host of multiple lasers, and capable of processing single, dual and quad wire simultaneously.

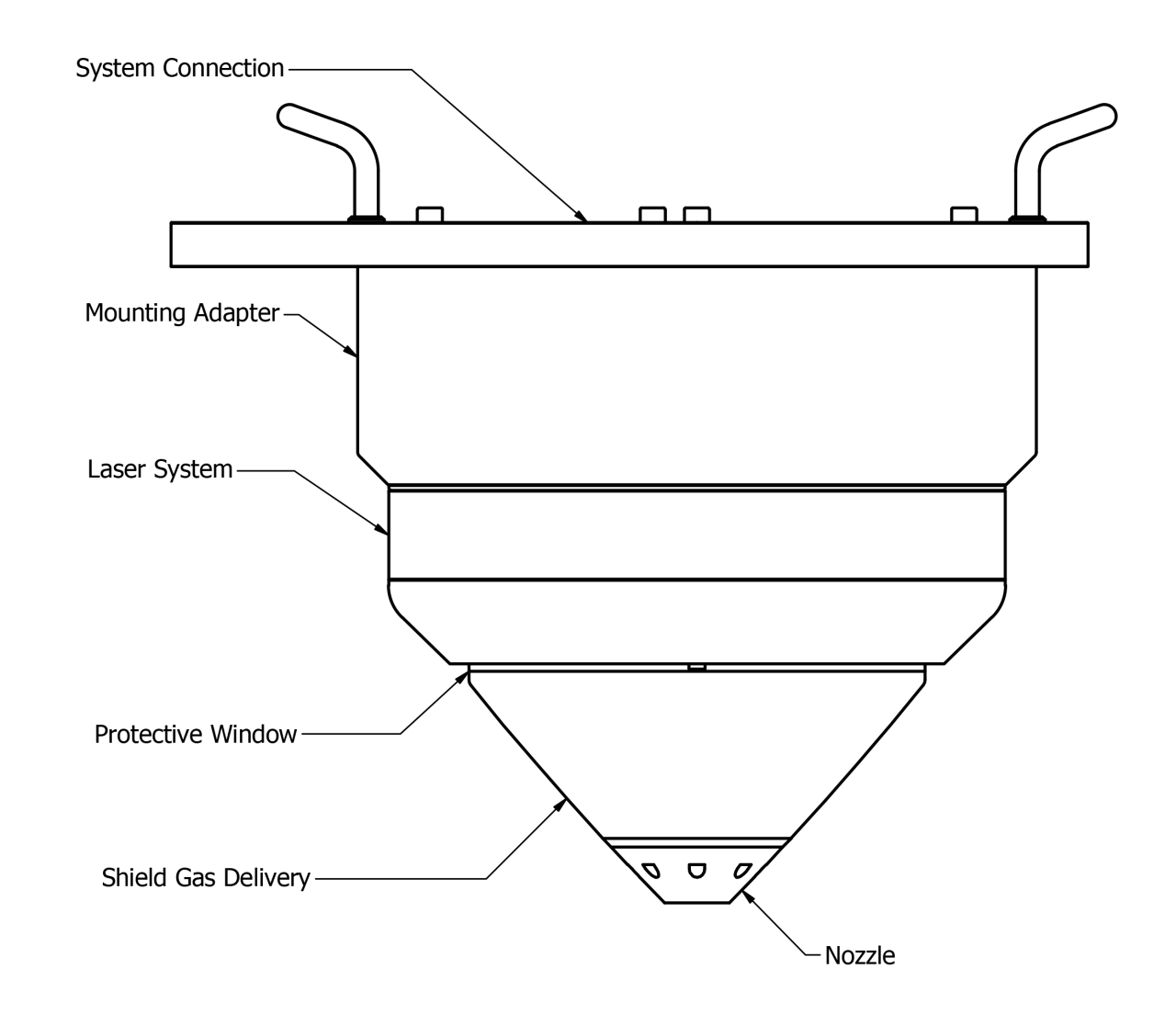

Integrated Wire Feed/s

Critical for high process reliability and unique to Meltio. Short distance from feeder to process is necessary for maximum wire feeding precision.

Coaxial Wire Feed

Can print geometries in any direction. Wire comes through the center of the melt pool thanks to the distributed laser system.

Shield Gas Ring

The head prevent oxidation through a large nozzle ring with very good gas distribution just a few millimeters from the melt pool.

Shield Gas Ring

The head prevent oxidation through a large nozzle ring with very good gas distribution just a few millimeters from the melt pool.

Integrated Process Control

Sensors monitor the laser fibers and the deposition process. The system will regulate automatically if an irregularity is detected, or put itself on hold in critical conditions.

PRODUCT LINEUP

Meltio’s solutions offer unparalleled opportunities for seamless 3D printing and CNC post-processing, enhancing your production capabilities while keeping costs low. With the use of standard, pure metal wire, our technology ensures reliable, high-density parts with proven structural integrity.

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier than ever thanks to the improved process control, advanced sensors and live monitoring allowing you to produce parts consistently 24/7.

The Meltio M600, with its built-in 3-axis probing system and work-holding solutions, is the ideal companion for your manufacturing operations.

Print Envelope (WxDxH):

300 x 400 x 600 mm

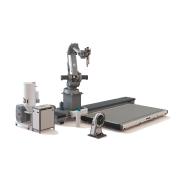

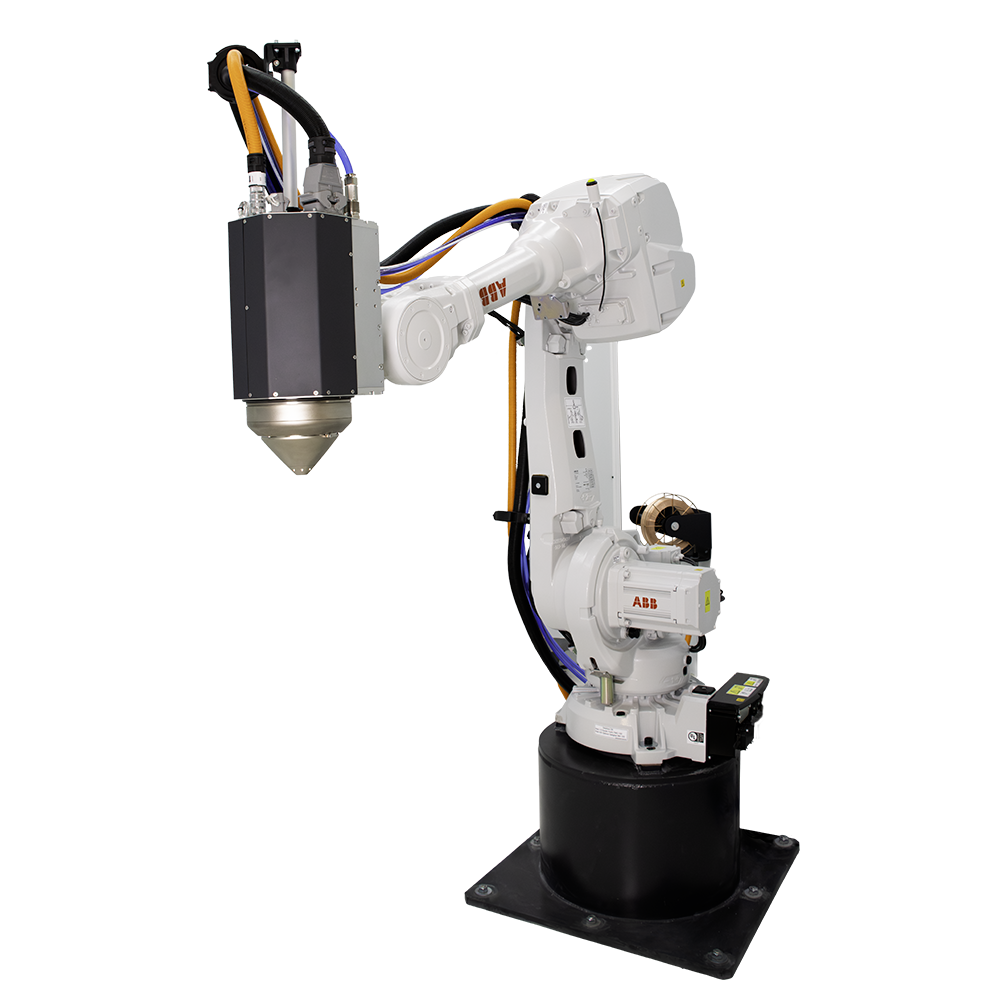

Turn a robot arm into a metal 3D printing system with no inherent size constraints. lt is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

The Meltio Engine integrates with any robot arm manufacturer and interface on the market. Meltio Space slicer software for robots is compatible with ABB, Kuka, Fanuc, Yaskawa and Siemens.

An affordable turn-key solution powered by the Meltio Engine Integration kit for Industrial Robots. It is designed to provide industries with a secure and efficient solution for manufacturing metal 3D printed parts.

The Meltio Engine Robot Cell is the most versatile and capable solution for 3D printing, repair, cladding, and feature addition.

UNLIMITED THIRD-PARTY MATERIAL CHOICE

MELTIO SPACE

A new perspective on 3D printing, specifically for robot systems, by breaking free from the limitations of 3-axis systems by incorporating advanced robotic manipulation capabilities including external axis like workpiece positioners or linear tracks.

Unlock Complex Geometry

Provides diverse toolpath strategies, avoiding limitations and enabling precise movements.

Best Value for Money

Combines affordability, advanced capabilities, and a user-friendly interface, maximizing investment and project outcomes.

Reduce Programming Time

Ensures accurate printing through virtual robot movement simulation and collision checks.

Ease of use

User-friendly interface with fully functional printing strategies pre-defined to exploit Meltio LMD capabilities.

Automated process parametrization

Optimize the performance of the Meltio Engine by fine-tuning process parameters for enhanced efficiency.

Automated process parametrization when defining only the Geometry (Solid or Hollow), the desired Quality (Utility or Fully Dense), and the Material.

This is defined automatically on Meltio Space:

-

Deposition Height and Widths

-

Material Selection (Dual Wire)

-

Overlaps, Infill Type, Infill Density and Angles, Seam

-

Speeds (Perimeters, infill, and travel speeds)

And also defines on Meltio Engine:

-

Laser Power, Feeder Speed, and Argon Flow

MELTIO SLICING STRATEGIES

More than 10 Slicing Strategies for industrial use

Combine and sequence different Slicing Strategies on only one manufacturing program, developed specifically for robot systems based on Meltio’s experience.

Planar Strategies

Conventional 3-axis slicing, horizontal or angled with up to two materials in the same process, limited by maximum overhang angle.

Ideal for simple geometries like pistons, drill bits, cranks, molds with internal conformal cooling channels, and differential growth heat exchangers.

Non-planar or Freeform based strategies

Cladding or coat single and double curvature surfaces and freeform surfaces with the strongest and high wear resistance materials.

Recover the life of dies and molds, as well as knives and or any worn part using just the necessary amount of material, with the best properties.

Add features or repairs on top of any surface like reinforcements, brackets, blades, teeth.

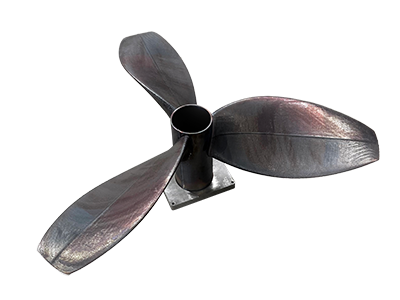

Radial strategies

Add features on bars or rods of your desired material and avoid machining large volumes of material, recommended for propellers (blades can be solid or hollow), camshafts, screw compressors, and mixers.

Coat, clad, or repair shafts and bars with the highest material properties.

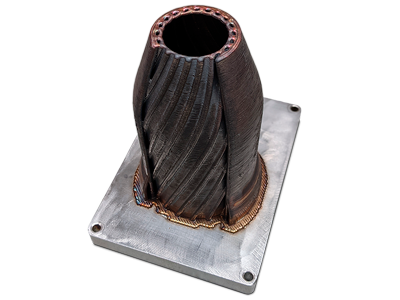

Strategies for Revolved Surfaces

Manufacture rotary symmetrical parts like rocket nozzles, vases, spherical, and cylindrical tanks with your desired thickness and the best surface quality with this slicing that follows the geometry.

Advanced Variable Deposition Strategies

Manufacture directly on top of flanges different curved pipes and manifolds without the need to depend on standard curvature radii to fit properly your design.

Admits also has pipes and manifolds with variable diameters along the part.

MELTIO SPACE ADVANTAGES

Intuitive

No previous expertise in robotics or programming is required thanks to a modern interface built specifically for wire-DED and robots.

Powerful

Multiple slicing options including variable deposition to address a wide variety of geometries with very fast calculation of complex toolpaths.

Post-processor

Meltio Space offers its users a diverse range of post-processors for the most popular robot brands, including predefined options such as: ABB (IO), ABB (OPC), ABB (Socket), KUKA (IO), FANUC (IO), YASKAWA (IO).

Investment Protection

Low capital and running costs. Includes continuous updates and predefined robot kinematic libraries.

Dependable

High success rate thanks to its kinematic model able to detect collisions along part creation even with part itself.

Tuned to Meltio LMD

A comprehensive set of advanced features to use Wire-LMD options like Dual Wire printing.

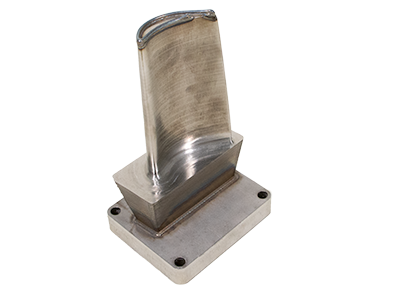

MELTIO APPLICATIONS

Aircraft Bracket

Titanium 64

Size:

109.6 x 160.8 x 34.8 mm

Weight:

2 kg

Dual Material Pipe

SS316L + Ni718

Size:

108 x 108 x 150 mm

Weight:

5 kg

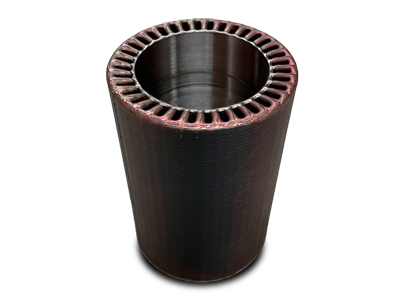

Rocket Nozzle

SS316L

Size:

117 x 117 x 180 mm

Weight:

3 kg

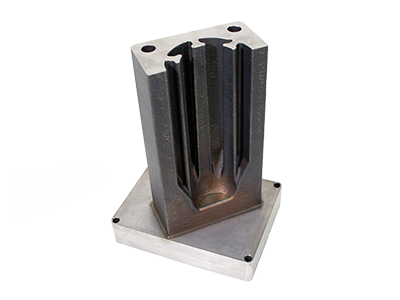

Injection Mold Half

SS316L

Size:

140 x 140 x 297 mm

Weight:

15 kg

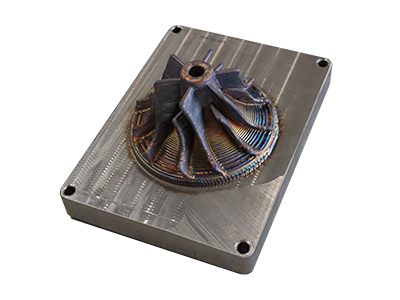

Turbo Impeller

SS316L

Size:

99 x 99 x 49.5 mm

Weight:

1 kg

MELTIO M600 APPLICATIONS

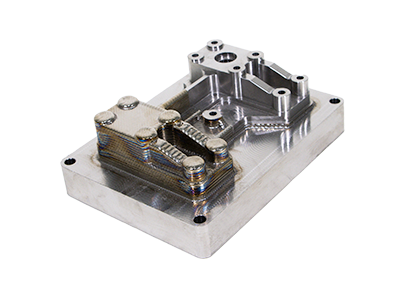

DM Combustion Chamber

Inconel 718 + Copper

Size:

131 x 200 x 176 mm

Weight:

6.4 kg

Bracket

SS316L

Size:

153 x 345 x 275 mm

Weight:

18.6 kg

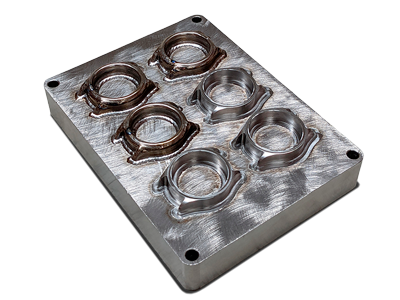

MELTIO ENGINE CNC APPLICATION

Watch Bezels

Titanium 64

Size:

50 x 45.9 x 12.7 mm

Weight:

0.25 kg

Elbow

SS316L

Size:

ext. 70 Ø – int. 50 Ø mm

Weight:

0.51 kg

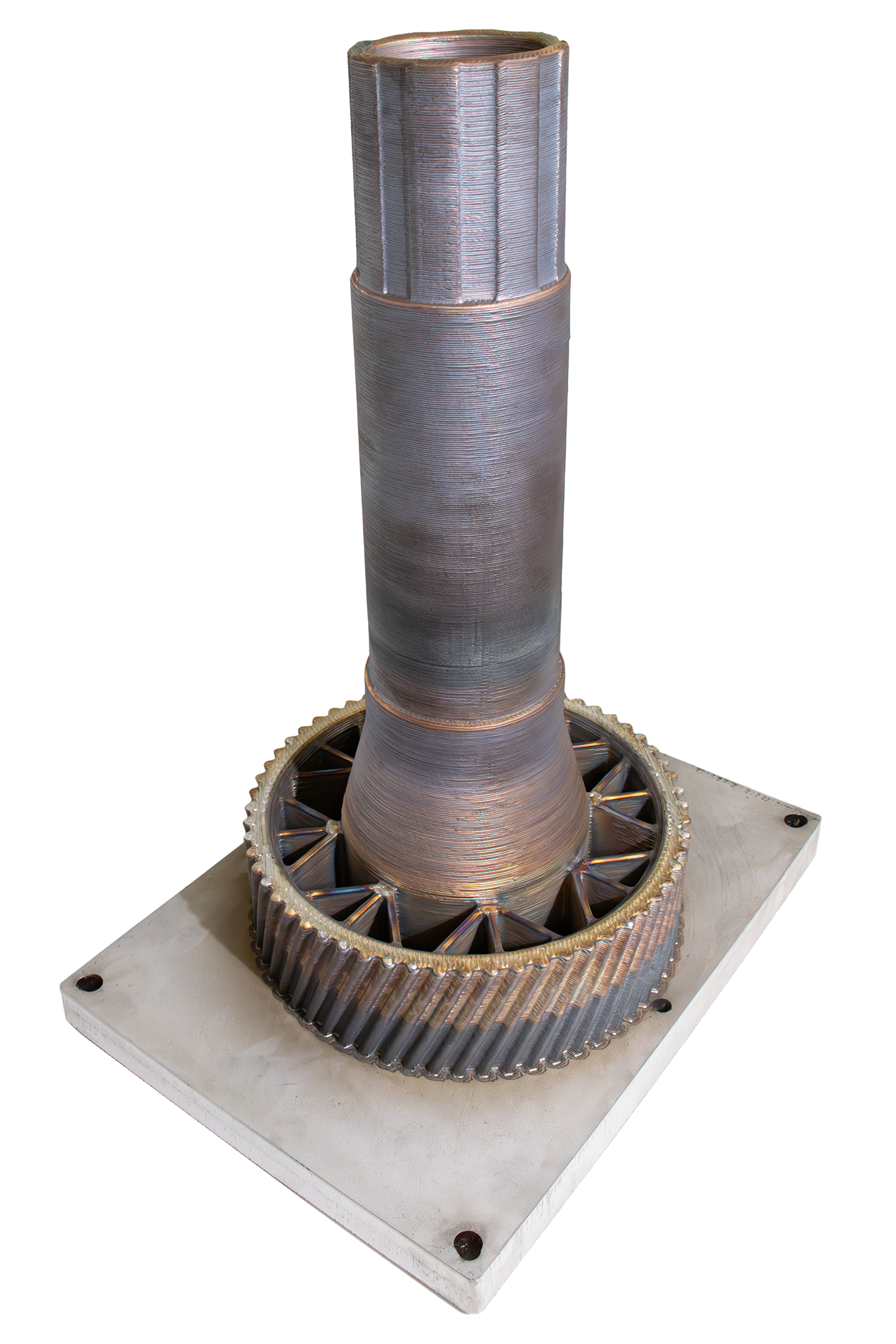

MELTIO ENGINE ROBOT APPLICATION

Rotary Screw Compressor

SS316L

Size:

75 x 75 x 230 mm cladded

Weight:

3 kg

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

CUSTOMER INQUIRIES

PLEASE FEEL FREE TO INQUIRE ABOUT ANY ADDITIONAL QUESTIONS YOU HAVE REGARDING ROBOTICS 3D PRINTING OR METAL POWDER REMOVAL.