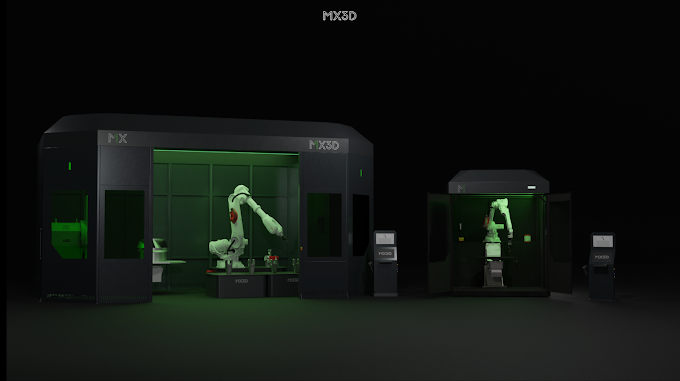

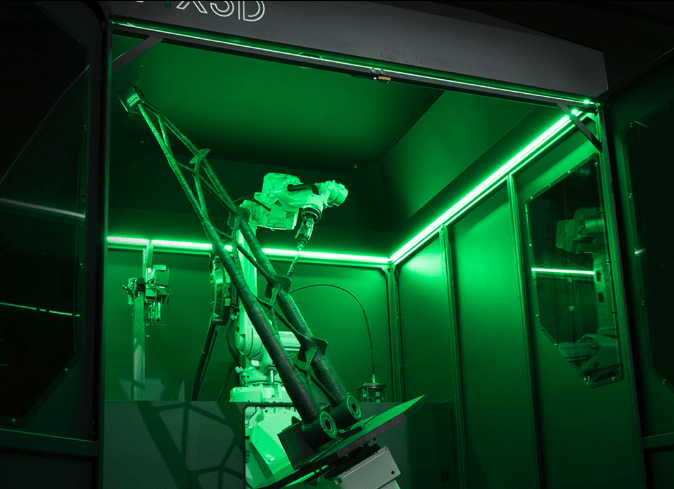

M-METAL AM SYSTEMS

The M-Metal AM Systems are built for WAAM. It offers a turnkey solution to get started with WAAM fast and print high-quality, medium-to-large-scale metal parts. The systems are fully integrated with MetalXL, MX3D’s dedicated WAAM-workflow for advanced process control/monitoring. The system is created with quality hardware components from renowned manufacturers.

PARTNERS & CLIENTS

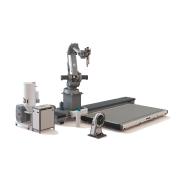

M1 METAL AM SYSTEM

The M1 Metal AM System offers a turnkey solution for printing high-quality, medium-to-large-scale metal parts. Built with quality hardware components from renowned manufacturers, the M1 Metal AM System also integrates MetalXL, MX3D’s dedicated WAAM-Workflow for advanced CAM, control/monitoring, and post-print data analytics.

The M1 Metal AM System includes:

- 8-axis ABB industrial robotics system enabling complex prints

- A Fronius GMAW/CMT welding machine

- MX3D MetalXL Software Suite

- MX3D MetalXL Control System including sensors network,

for intelligent automation, real-time print monitoring, and high-resolution data logging.

MX METAL AM SYSTEM

For companies that want to print larger metal parts in-house, the MX Metal AM System is a new turnkey robotic metal AM system for printing qualified metal parts fully tailored to customers’ requests. includes an enlarged 8-axis heavy-duty industrial robot, high productivity power source and automation tools, all fully integrated with MX3D’s MetalXL E2E workflow software and control system.

The MX Metal AM System includes:

- An enlarged 8-axis heavy-duty industrial robot

- High productivity power source and automation tools

- MX3D MetalXL Software Suite

- MX3D MetalXL Control System including sensors network,

for intelligent automation, real-time print monitoring, and high-resolution data logging.

BENEFITS

MANUFACTURING

SPEED

The M – Metal AM Systems incorporates heavy duty power source to print up to 10kg/hour. This high deposition rate allows consequent lead time reduction compared to con-ventional metalwork processes (CNC, forging, casting, etc.) and other metal AM processes (LPBF, DED-Laser, etc.).

ALL IN ONE

METAL XL CAM

MetalXL CAM is the dedicated interface for path planning, which includes an extensive printing strategy library for various metal alloys, feasibility check tools and advanced slicing/solving

METAL XL LIVE

MetalXL Live is the print monitoring interface. It allows the user to simulate the print, control the process in real time and log the data thanks to the MetalXL control system.

METAL XL VIZ

MetalXL Viz, for post-printing analytics. it displays a 3D report of the acquired data for extensive post-printing analytics, for defects detection, certification of the printed parts and strategy refinement.

CONTROL SYSTEM

Better, faster and easier industrial 3D metal printing

MetalXL comes with an intelligent MetalXL Control System directly connected to the robotic WAAM system for enhanced print performance. It improves consistent performance and productivity by smart sensors for continuous monitoring while supporting the operator with real-time feedback and advanced insights into the printing proces

MATERIAL LIBRARY

Built-in metal alloy library with verified and tested WAAM process parameters

AUTOMATIC CALIBRATION

Add new alloys and specific parameters with the automatic calibration tool

PRINTING STRATEGIES

Multiple printing strategies available for optimizing the print quality

SMART SENSORS

Enhanced productivity and material performance due to smart sensors

![]()

REAL-TIME CONTROL

Direct control and operator feedback on print process and performance

![]()

CONTINUOUS MONITORING

Live process monitoring and simulation, including automated issue detection

![]()

HIGH-RESOLUTION DATA LOGGING

Advanced WAAM parameter logs for print quality analysis and validation

![]()

3D-VISUALISATION

Improved insights into the printing process due to 3D visualization tools

CERTIFICATION & QUALIFICATION

WAAM IN ENERGY

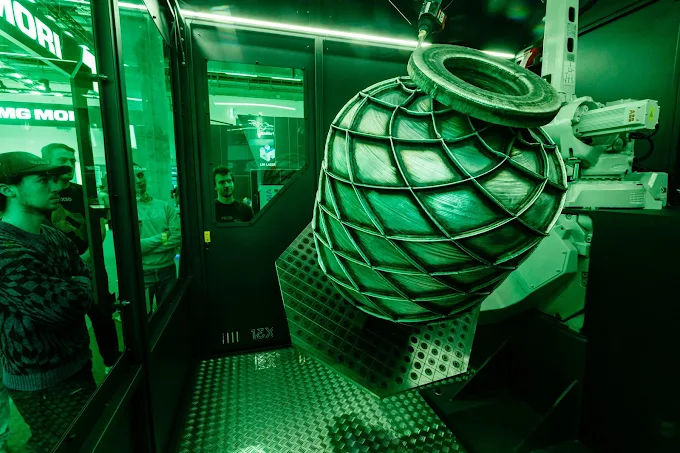

![home-website-mx3d [Hersteld]](https://mx3d.com/wp-content/uploads/2024/12/pressure-vessel-mx3d-industries-energy-1030x1020.jpg)

PRESSURE VESSEL

Our reinforced Pressure Vessel is a clear sign that our proprietary WAAM technology is ready for industrial application. By using MX3D’s dedicated WAAM Software and Systems it’s possible to overcome challenges faced by Industries like energy, manufacturing, and maritime. Key industry benefits are lead time reduction, quality improvement, and cost-effectiveness.

The 52-kilogram pressure vessel was printed in Aluminum using our proprietary MetalXL software and M1 Metal AM System, reaching a total print time of 3 days.

VALVE

MX3D’s Wire Arc Additive Manufacturing (WAAM) delivers high-quality parts with excellent lead times. Ideal for the energy industry. This 750kg carbon steel valve was printed in only 180 hours on a our turnkey M1 Metal AM System. The material properties of the printed part exceed the conventional casting process, with a quality similar to a forged component.

IMPELLER

MX3D is an expert in printing NiBrAl (CuAl8Ni2) and SS316 impellers and propellers with WAAM.

The ability to print parts locally, fast and fully automated helps to solve critical supply chain problems. Customer such as ENGIE for the shown NiBrAl impeller, regain control over urgently needed parts and can reduce their stock volume.

WAAM IN MANUFACTURING

PULPER SCREW

The “Pulper screw” is a >600 kg print for the heavy processing industry, it’s printed with one of our WAAM dedicated M-Systems the M1 Metal Metal System, using 316L stainless steel supplied by Wedling Alloys.

To leverage the print we used our complete range of control tools and MetalXL add-ons, including the 3D Scanner and Melt Pool Camera.

MOLD

WAAM advances small serial production, especially for complex geometries and customized parts. With MetalXL, our dedicated WAAM solution, you can print several components at the same time with diverse strategies, to further optimize your manufacturing capabilities.

WHEEL BRACKET

Due to their unique designs, custom large-scale metal parts are very costly to manufacture with conventional processes (e.g. CNC, casting) and can involve extensive lead time.

WAAM allows manufacturing unique parts with any weldable alloy in a fast and cost-effective way

WAAM IN MARITIME

BRONZE PROPELLER

The maritime sector needs to adopt advanced materials with a smaller environmental footprint that are less costly and easier to maintain. Through WAAM, it is possible to create lightweight, high-performance materials to manufacture hollow propeller blades to improve performance on the original design with optimal durability.

These propellers are printed in NiBrAl and post-processed afterwards, showcasing two of the most common blade shapes.

ALUMINIUM BULB KEEL

The keel is a flat blade that prevents the boat from being blown wayward by the wind and also holds the ballast that keeps the boat right-side up. WAAM eases the product development of keel systems, responding to the needs of each custom yacht, and can assure high performance.

This 4m long, 8mm thick bulb keel incorporates internal stiffeners to improve its structural integrity. Its surface is finished manually, and the internal volume is filled with lead.

ALUMINIUM COWL VENT

KM Yachtbuilders partners with MX3D to 3D print aluminium yacht parts aiming to produce their unique parts efficiently and cost-effectively and print industrial metal parts on-site. The research was in part funded by the Netherlands Enterprise Agency (RVO).

Despite its modest size, a high-end cowl vent can take a lot of effort to construct. MX3D printed this aluminium cowl vent in one session; coated and painted on the inside, and its surface has been manually finished.

WAAM IN ARCHITECTURE

SOLSTICE BRIDGE

The Solstice Bridge is designed by Cyrus Clark, an architect for the city of Amsterdam. The pedestrian bridge spans 30 meters long over the Oostenburgervaart, a canal on the east side of the city centre. The search for a uniquely defining design element led to the concept of 360 subtly different handrail balustrade poles, each one slightly different from the previous one in a transitioning motion.

The handrails are 3D printed using WAAM , the large quantity of all different poles made this and ideal fit for the MX3D industrial 24/7 3D printing capability.

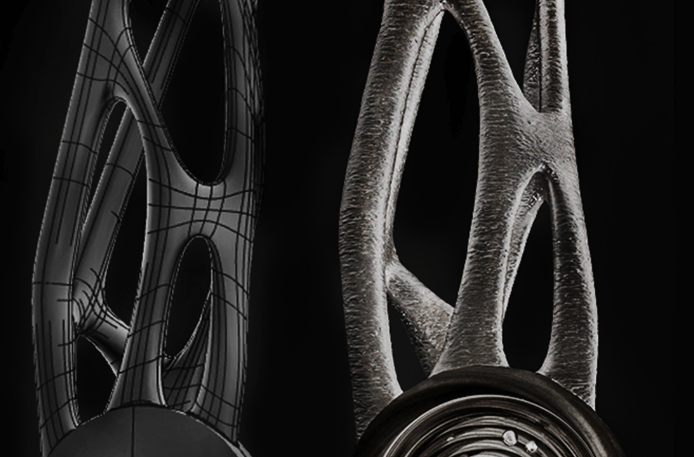

MX3D BRIDGE

MX3D 3D printed a fully functional stainless steel bridge to cross one of the oldest and most famous canals in the centre of Amsterdam.

The MX3D Bridge is designed by Joris Laarman Lab and engineered by Arup, additional expertise were provided by ArcelorMittal, Autodesk, Heijmans, Lenovo, ABB, Air Liquide & Oerlikon, Plymovent, and TU Delft. The municipality of Amsterdam is the first customer of our collaborative bridge-building department.

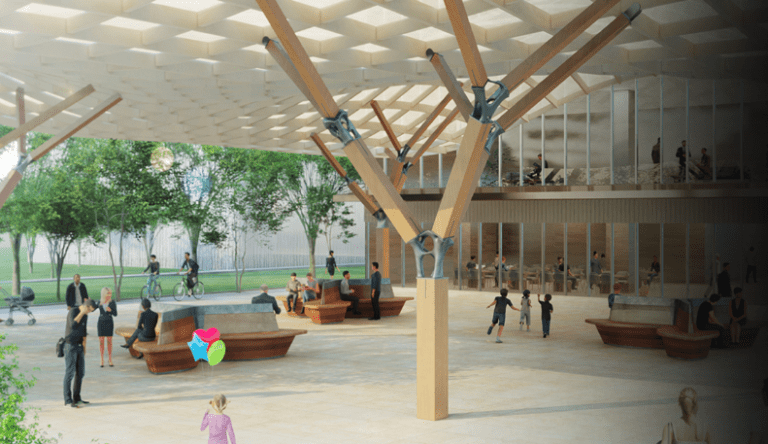

TAKENAKA STEEL CONNECTOR

Takenaka project shows the progress in the production of highly customized and engineered steel connectors using robotic WAAM, with the goal to automate both the design and production of complex components for large structures in the architecture industry.

The Duplex stainless steel Connector’s net weight is 40Kg reaching up to 45Kg after its hollow core was filled with approximately 2.5 liters of mortar.

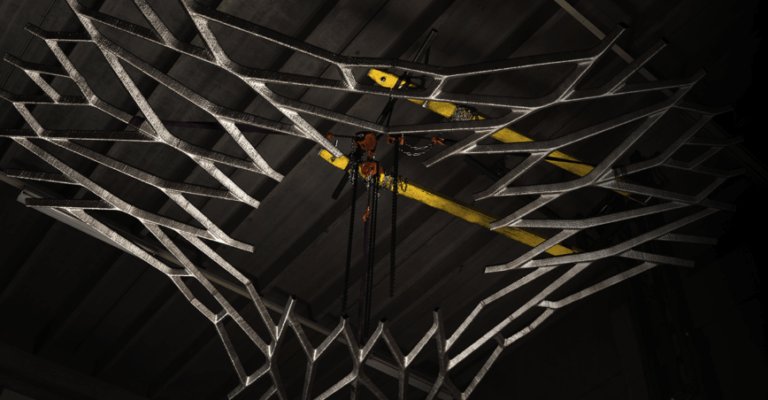

OPTIMIZED TRUSS

A set of optimized metal trusses has been 3D-printed with robotic WAAM based on an end-to-end framework for additive manufacturing by the INTEGRADDE consortium. The optimization-initiated workflow incorporates detailed design and FE verification steps performed prior to additive manufacturing with robotic Wire Arc Additive Manufacturing (WAAM).

Together with the INTEGRADDE partners, MX3D has developed an innovative production strategy of continuous and integral control of the WAAM process, from product design to final verification, in-line quality assurance for the manufacturi

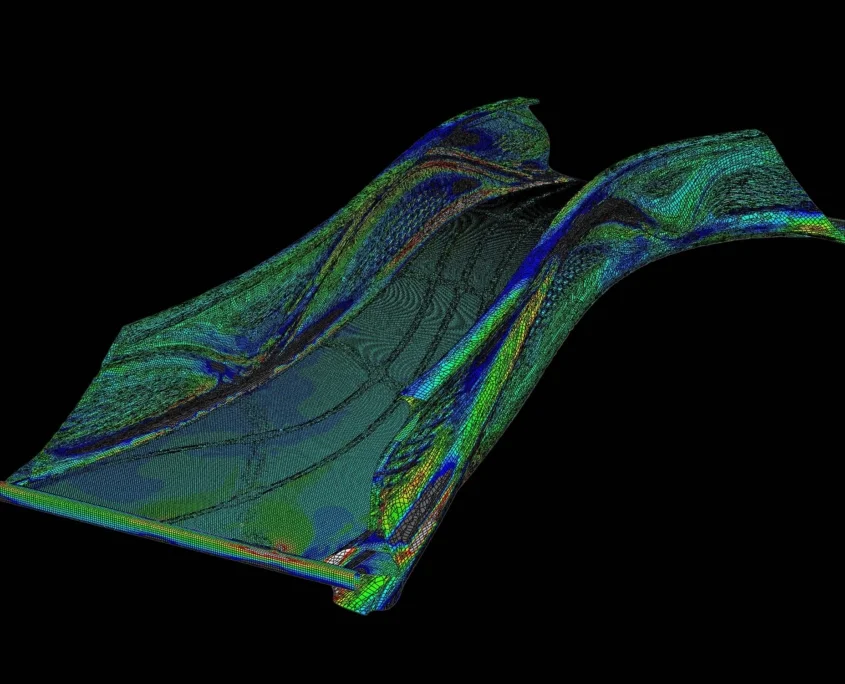

ESA FLOOR

Together with the European Space Agency (ESA) and Skidmore, Owings & Merril (SOM), MX3D developed and produced a 1:1 scale, optimized, 3D printed floor structure for the LunarVillage.

It shows the potential of our robotic WAAM technology to create approved, lightweight & complex structures. Now even faster and more reliable due to our in-process MetalXL Control System.

CERTIFICATION & QUALIFICATION

To ensure the safety and quality of fully printed structures such as the MX3D Bridge and Takenaka’s Structural Steel Connector, the parts undergo rigorous testing by MX3D’s partners such as Imperial College London, Bologna University, and Lloyd’s Register (LRQA).

MX3D produces parts with similar or higher mechanical properties comparable to those of cast or wrought material. By adopting international standards, MX3D manages the quality of parts for various industries and applications.

CUSTOMER INQUIRIES

PLEASE FEEL FREE TO INQUIRE ABOUT ANY ADDITIONAL QUESTIONS YOU HAVE REGARDING ROBOTICS 3D PRINTING OR METAL POWDER REMOVAL.