CEAD

Benefits of using a robotic arm for 3D printing

Original Source :

https://ceadgroup.com/portfolio-items/producing-locally-additive-manufacturing-microfactory/

Content Written by CEAD

From mold making to 3D printing boats, large format additive manufacturing (LFAM) is quickly adopted across various industries. This leads more new industries, enterprises and universities to additive manufacturing. Choosing how you print at scale, however, still matters enormously. There are many different systems, processes and technologies available. One of these choices is between a gantry-based system or a robotic-based system.

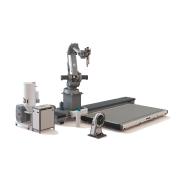

Robotic-based systems, like CEAD’s Flexbot, offer a compelling option thanks to their flexibility, expandable build volumes, and seamless integration of hybrid manufacturing.

Below, we outline the core benefits and what they mean in practice for engineering teams, production managers, and innovators bringing big ideas to life.

1. Flexibility by design

The main advantage of robotic 3D printing can be found in the characteristics of the robot itself. Industrial robots bring six degrees of freedom (XYZ + ABZ) to large-scale printing, with the option to add a 7th axis via a linear track.

In practical terms, that means:

Greater design freedom for overhangs, angled features, and multi-directional deposition. This eliminates the need for support structures and decreases the material needed for a tool.

Configurable work cells that can evolve, by adding a rotary table, a second robot, or dedicated post-processing without redesigning your entire line.

Easier relocation compared to fixed gantries; robot cells can be reconfigured as factory layouts change.

Taken together, robotic kinematics provide not just more ways to move the nozzle, but a practical way to design better parts, run more efficient cells, and adapt as programs scale without rebuilding your production line.

2. Hybrid manufacturing

Robotics make it straightforward to combine processes in one cell and move from raw pellet to ready-to-use part under a single control stack. The result is shorter lead times, tighter tolerances, and less manual handling.

CEAD’s Flexbot drastically increases production flexibility and speed by combining additive manufacturing (3D printing) with subtractive manufacturing (CNC-milling) in one cell. After printing a piece, the robot can automatically switch from printing to milling. With one single process, re-clamping or extra scanning is no longer necessary after printing. No re-clamp means fewer handling marks, less variability, and more consistent surface finishes and hole positions across batches.

A hybrid manufacturing system can CNC-mill the workpiece, drill, place threaded inserts or bushing and sand the part for a smooth finish. CEAD’s Flexbot is built for exactly this: modular hardware, multi-process toolheads, and software workflows (e.g., G-code driven toolpaths) that minimize handovers and manual setups. All in one automated production process.

3. Scalable, modular and future-proof designs

Robotic 3D printing is built to grow step by step, so you can start with a cell that fits today’s program and expand as requirements evolve:

Begin with a compact cell on a pedestal and, when the parts get longer, swap the pedestal for a linear track and extend the rail to increase reach. Or even to upgrade the print bed for a rotary table to increase production speed and build volume even more.

Widen the fixture or print bed as envelopes grow.

Add a second robot for tandem printing or to dedicate one arm to finishing while the other prints.

Add on milling later to bring critical faces to tolerance.

Because the set-up of the system is modular, you evolve materials, tooling, and workflows without replacing the base machine or reworking your facility, keeping initial investment lean while leaving clear, low-friction paths to scale.

4. Synchronized printing

While gantries can travel fast, real-world print speed is often limited by material cooling and layer adhesion windows. Robotic cells make it easier to keep the system productive, for example by printing a second identical part while the first reaches its optimal interlayer temperature, or by splitting operations across two robots to avoid idle time.

5. G-code driven robotic manufacturing

CEAD’s approach brings true CNC discipline to robotics: the Comau robotic arms used in the Flexbot are compatible with Siemens Sinumerik Run My Robot, allowing the electrical cabinet to communicate directly with the robot for lower latency and higher accuracy, whereas other robots typically require their own controller, adding an extra communication layer that slows response to adjustments.

Just as important, Sinumerik is already the daily driver in many CNC shops, so programmers stay in a familiar G-code workflow, existing post-processors and best practices carry over, operators and maintenance teams face minimal retraining, and your current service, QA, and data infrastructure (tool libraries, offsets, probing cycles, logging) can be reused. Reducing ramp-up time and de-risking adoption while unifying additive and subtractive under one control environment.

6. Safety first

Where gantry solutions operate in a closed environment, robotic 3D printers generally deployed in open cells protected by safety cages rather than full enclosures. Therefore, large industrial robots demand mature safety.

CEAD’s approach combines safety cages (fences) with interlocked doors and virtual software safety zones. If a gate is opened, the system triggers an emergency stop; software limits keep the robot within defined boundaries. Designs and documentation align with relevant CE and electrical standards (e.g., NEN-EN IEC 60204) so owners can validate compliance and keep teams protected.

In the video below, CEAD’s co-founder and CTO Maarten Logtenberg dives into the importances of safety measures for robotic 3D printing.