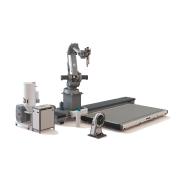

Advanced Additive Manufacturing System

An affordable turn-key solution powered by the Meltio Engine Integration kit for Industrial Robots. It is designed to provide industries with a secure and efficient solution for manufacturing metal 3D printed parts.

The Meltio Engine Robot Cell is the most versatile and capable solution for 3D printing, repair, cladding, and feature addition.

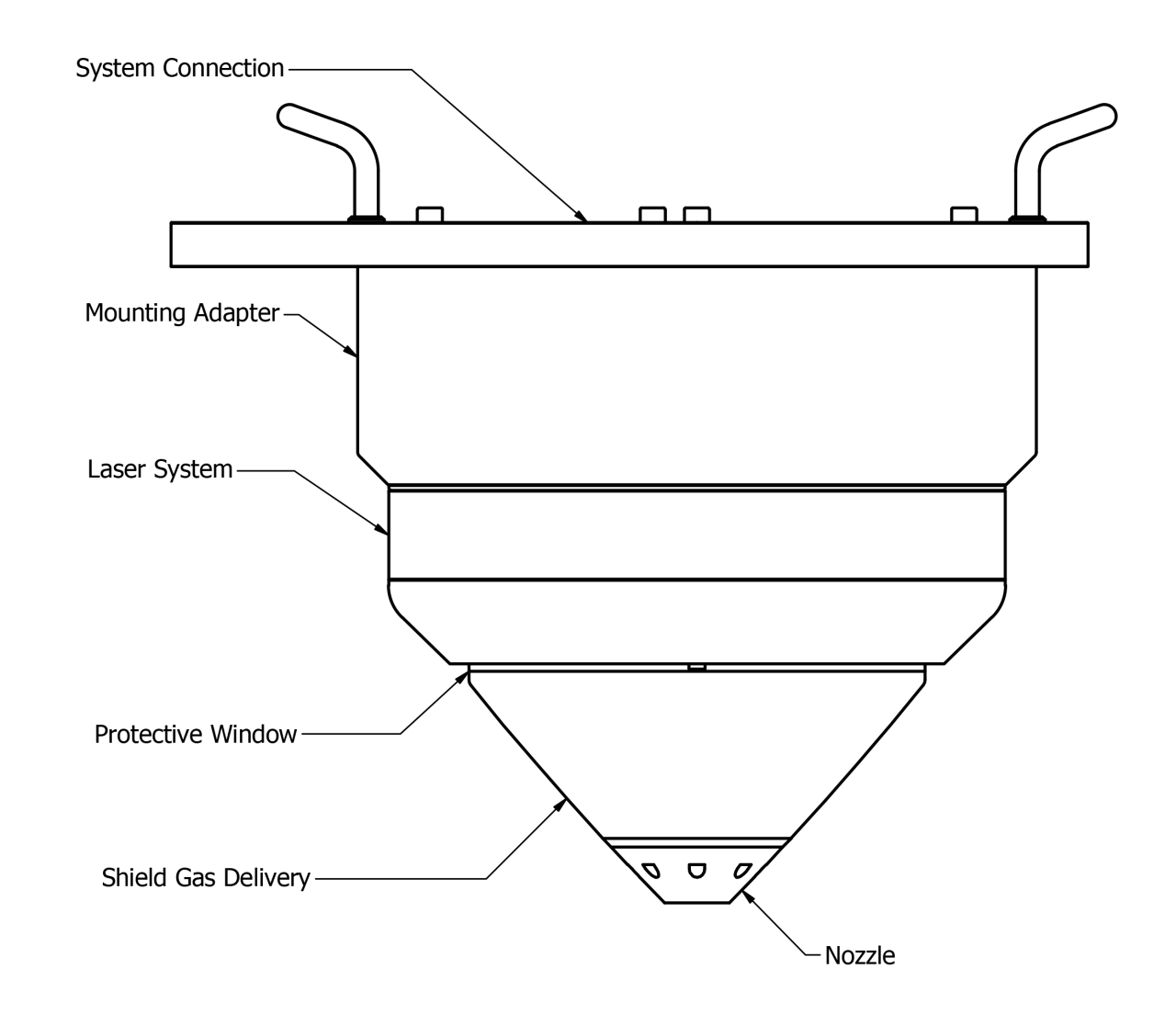

MULTI-LASER BLUE DEPOSITION HEAD

Enhance performance and reliability

Augmented energy delivery efficiency reduces energy consumption, making it a cost-saving process, thanks to the blue laser diodes

Blue Light

450 nm light improves energy absorption and printing efficiency across the metal material spectrum.

No Calibration

It arrives aligned from the factory for maximum printing repeatability and minimal maintenance.

Hotwire Compatible

The deposition head is developed to used with an optional hotwire supply to increase the deposition rate and allow for more materials to be processed.

High Efficiency

The energy consumption per component is reduced significantly, resulting in a greener and more cost-efficient process.

MELTIO ENGINE BLUE SPECIFICATIONS

-

Laser SystemBlue laser (higher absorption & power efficiency; wider range of compatible materials than IR).

1000 W, 9 × 450 nm direct diode lasers -

PrintheadRobot mounted, 20.5–23 kg

-

Printhead Size (WxDxH)262 × 272 × 572 mm

-

Control UnitWall‑mounted, air‑cooled; 80.5 kg; 600 × 300 × 800 mm. Separate wall‑mounted 27″ HMI.

-

CoolingWater‑cooled deposition head. Chiller included.

-

Print Envelope (WxDxH)Depending on robot’s reach

-

Process ControlMelt pool camera & closed‑loop wire modulation

-

Slicer SoftwareMeltio Space (1‑year subscription included)

-

Feeder SystemQuad‑point traction servomotor feeder, frictionless liners

-

Wire FeedstockDiameter: 0.8–1.2 mm / Spool Type: 8S300; external wire drum ready

-

Product ConfigurationsSingle or Dual Wire

-

Compatible MaterialsStainless steels, carbon steels, tool steels, nickel alloys, titanium, copper alloys, gold alloys, and more

-

Load500 kg max load (standard)

-

No Positioner Interpolation2000 × 1000 × 1000 mm

-

Custom Build PlatformNot included

-

MovementNo positioner movement; robot tool orientation only

-

Positioner Interpolation⌀ 1000 mm × 1200 mm

-

Actively Cooled Build Platform

- Buildplate 300 × 400 mm

- Buildplate 150 × 200 mm

- Buildplate 120 × 100 mm

* Cooling bed controls print temperature and protects the positioner/hardware from exceeding 70 °C for periods > 24 h.

UNLIMITED THIRD-PARTY MATERIAL CHOICE

MELTIO SPACE

A new perspective on 3D printing, specifically for robot systems, by breaking free from the limitations of 3-axis systems by incorporating advanced robotic manipulation capabilities including external axis like workpiece positioners or linear tracks.

Unlock Complex Geometry

Provides diverse toolpath strategies, avoiding limitations and enabling precise movements.

Best Value for Money

Combines affordability, advanced capabilities, and a user-friendly interface, maximizing investment and project outcomes.

Reduce Programming Time

Ensures accurate printing through virtual robot movement simulation and collision checks.

Ease of use

User-friendly interface with fully functional printing strategies pre-defined to exploit Meltio LMD capabilities.

Automated process parametrization

Optimize the performance of the Meltio Engine by fine-tuning process parameters for enhanced efficiency.

Automated process parametrization when defining only the Geometry (Solid or Hollow), the desired Quality (Utility or Fully Dense), and the Material.

This is defined automatically on Meltio Space:

-

Deposition Height and Widths

-

Material Selection (Dual Wire)

-

Overlaps, Infill Type, Infill Density and Angles, Seam

-

Speeds (Perimeters, infill, and travel speeds)

And also defines on Meltio Engine:

-

Laser Power, Feeder Speed, and Argon Flow