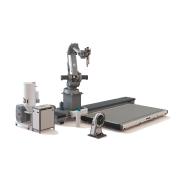

THE PRO-VERSION FOR LARGE PARTS WITH HEIGHTS UP TO 1,000 MM

The SFM-AT1000-S is a high-capacity automated depowdering system engineered for large and heavy metal components, accommodating parts up to 1,000 mm in height and weighing up to 800 kg. Designed to meet the stringent post-processing standards of the aerospace sector, it delivers fully automated, highly efficient cleaning — reaching deep into internal cavities and intricate channels, making it ideal for even the most complex rocket engine geometries.

PART

| Dimensions | 600 x 600 x 660 mm 600 x 600 x 1,000 mm |

| Weight | up to 800 kg (incl. build plate) |

TWO SWIVEL ARM

OPTIONS

The SFM-AT1000-S features two infinitely rotating servo-driven axes, enabling precise part movement along any programmable path. It is offered in two configurations: a long swivel arm for general applications and a short swivel arm designed for parts with a low center of gravity — ideal for components such as those produced on the NXG XII 600.

EASY FRONT-TOP

LOADING

The innovative front-top loading mechanism allows the upper door and frame to lift together, providing direct access to the rotary table. This eliminates the need to “thread” parts in from above, making it significantly easier to load heavy components by crane.

INTELLIGENT DEPOWDERING

WITHOUT PROGRAMMING

Fully compatible with SPR-Pathfinder® software (serial number 1 and above), the SFM-AT1000-S automatically generates optimized motion paths from CAD data for each build job. This ensures complete powder removal, even from complex internal geometries — without the need for manual programming.

SFM-AT1000-S PRODUCT DETAILS

-Automated, unlimited 2-axis swivel device

-Vibrator with a wide frequency range

-Manual depowdering (with compressed air or inert gas) of residual powder via sealed glove ports

-Manual control by joystick

- Powerful dust removal for non-reactive materials

- Inert gas infusion for reactive materials in accordance with ATEX

- Direct connection to a recycling unit

- SPR-Pathfinder® software for simulating and programming the cleaning program

- Programmable knocker

- Digital-Factory-Tool for quality assurance and automation integration

- OPC UA interface (Industry 4.0-capable)

- Front-top loading

- Short swivel arm for optimal center of gravity

-

TECHNICAL DATA Machine dimensions (W x D x H) 2,110 x 1,580 x 2,260 mm Installation space (W x D x H) 3,600 x 2,600 x 3,500 mm Weight 1250 kg Supply voltage / frequency 400 / 50 – 60 V/Hz Power consumption 1.8 kW Power connection 16 A PART Weight max. 800 kg Dimensions up to 600 x 600 x 660 mm

or 600 x 600 x 1000 mm