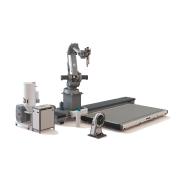

THE ENTRY-LEVEL SYSTEM FOR MEDICAL PARTS AND LABORATORY APPLICATIONS

The SFM-AT200 is the most compact system in Solukon’s lineup, engineered for efficient and thorough cleaning of laser-melted metal components. Combining top-tier safety, functionality, and durability, it offers user-friendly operation in a space-saving design — making it an ideal choice for medical devices, research environments, and laboratory applications.

RELIABLE AUTOMATED

POWDER REMOVAL

The smallest depowdering system from Solukon is based on the unique Smart Powder Recuperation® technology. With adjustable vibration and rotation, it removes excess powder from even the most complex cavities and support structures. The horizontal axis automatically swivels by approx. 350 degrees, while the rotary table can be adjusted by hand. In addition, the frequency of the vibration system can be set as required.

DEPOWDERING REACTIVE

MATERIALS

Since the SFM-AT200 has no ignition sources, it can also be used to safely clean parts made of reactive materials such as aluminum or titanium. Inerting with protective gas ensures fully reliable explosion protection.

The recovered metal powder can be reused and is available for other printing jobs.

SFM-AT200 PRODUCT DETAILS

- Automated swivel device

- Rotary table for manual positioning of the part

- Material lock with special container for collecting metal powder

- Vibrator with a wide frequency range

- Powerful dust removal for non-reactive materials

- Inert gas infusion for reactive materials in accordance with ATEX

- Direct connection to a recycling unit

-

TECHNICAL DATA Machine dimensions (W x D x H) 1,160 x 985 x 1,139 mm Installation space (W x D x H) 2,200 x 2,400 x 2,200 mm Weight 150 kg Supply voltage / frequency 400 / 50 – 60 V/Hz Power consumption 0.4 kW Power connection 16 A PART Weight max. 100 kg Dimensions up to 300 x 300 x 230 mm