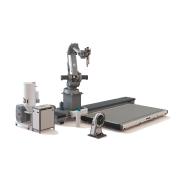

THE NEW STANDARD FOR MEDIUM-SIZED PARTS

The SFM-AT350 is a fully automated depowdering system designed for medium-sized, laser-melted metal components in additive manufacturing. Engineered with an optimally utilized chamber and advanced intelligent functions, it delivers exceptional cleaning performance — setting a new benchmark for post-processing medium-sized metal parts.

FOR PARTS UP TO

400 X 400 X 400 MM

The low chamber volume of the SFM-AT350 is utilized for maximum efficiency. With a special arm design, the depowdering system can accommodate parts up to 400 x 400 x 400 mm or 500 x 280 x 400 mm that weigh up to 100 kg. The SFM-AT350 has an extremely compact footprint and low inert gas consumption. It provides the best cost:footprint ratio of any system.

SFM-AT350-E:

ULTRASONIC DEPOWDERING

As an alternative to standard machines, the SFM-AT350-E is available with piezoelectric excitation. It cleans parts very gently by using very high, self-regulating ultrasonic vibration. Ultrasonic cleaning is ideal for delicate structures like those of medical parts, for example.

INTELLIGENT DEPOWDERING

WITHOUT PROGRAMMING

Fully compatible with SPR-Pathfinder® software (serial number 1 and above), the SFM-AT800-S automatically generates optimized motion paths from CAD data for each build job. This ensures complete powder removal, even from complex internal geometries — without the need for manual programming.

SFM-AT350 PRODUCT DETAILS

- Automated 2-axis swivel device

- Rotary table with infinite rotation

- Material lock with special container for collecting metal powder

- Vibrator with a wide frequency range

- Manual depowdering (with compressed air or inert gas) of residual powder via sealed glove ports

- Powerful dust removal for non-reactive materials

- Protective gas inertization for reactive materials in accordance with ATEX

- SPR-Pathfinder® Software for simulating and programming the cleaning program

- Programmable knocker

- Digital-Factory-Tool

- OPC UA interface

- Ultrasonic depowdering (SFM-AT350-E)

| TECHNICAL DATA | |

|---|---|

| Machine dimensions (W x D x H) | 1,310 x 1,100 x 2,140 mm |

| Installation space (W x D x H) | 2,300 x 2,300 x 2,300 mm |

| Weight | 650 kg |

| Supply voltage / frequency | 400 / 50 – 60 V/Hz |

| Power consumption | 1.0 kW |

| Power connection | 16 A |

| PART | |

|---|---|

| Weight | max. 100 kg |

| Dimensions | up to 400 x 400 x 400 mm or 500 x 280 x 400 mm |