SOLUKON IS THE DEFINITION OF DEPOWDERING

POST PROCESSING PROCESS IN METAL ADDITIVE MANUFACTURING IS VERY IMPORTANT.

SOLUKON MASCHINENBAU GMBH WAS THE FIRST COMPANY TO INDTRODUCE THE CONCEPT OF METAL DEPOWDERING AND INTRODUCE IT AS A PRODUCT TO THE MARKET.

NOW SOLUKON IS THE DEFINITION OF DEPOWDERING.

NUMBER OF COUNTRIES INSTALLED

NUMBERS OF MACHINE INSTALLED GLOBALLY

PATENT APPLICATIONS

TRUSTED BY INDUSTRY LEADERS

LEADER IN AUTOMATED DEPOWDERING

Solukon sets the standard in powder removal for metal additive manufacturing. With patented SPR® (Smart Powder Recuperation) technology, Solukon systems automate the depowdering of complex, intricate parts — enhancing safety, improving quality, and ensuring full regulatory compliance.

Solukon was the first to implement the concept of Depowdering. Since then on, we have developed our portfolio focusing on this.

Over 350 units have been installed over 26 countries. Solukon has the most experience in when it comes to depowdering metal and powder parts.

Compared to Manual Depowdering, Solukon along with 2 Axis Endless Rotation, we have various excitation methods to remove powder from complex parts.

PATHFINDER, THE SOFTWARE TO SIMULATE AND CALCULATE DEPOWDERING

SPR-Pathfinder® uses the CAD file of the entire build job to simulate and calculate the optimal motion sequence for efficient powder removal, even from complex internal geometries. These calculations are based on a digital twin of the part.

What makes it stand out: SPR-Pathfinder® allows you to simulate depowdering during the design stage, helping you verify whether your part geometry is depowderable before printing.

The software calculates depowdering paths for each specific build job, enabling the simultaneous simulation and cleaning of multiple different components on a single build plate.Intelligent depowdering is the game-changer for the fully automated serial cleaning of parts in additive manufacturing. Solukon offers a unique tool for this: SPR-Pathfinder®.

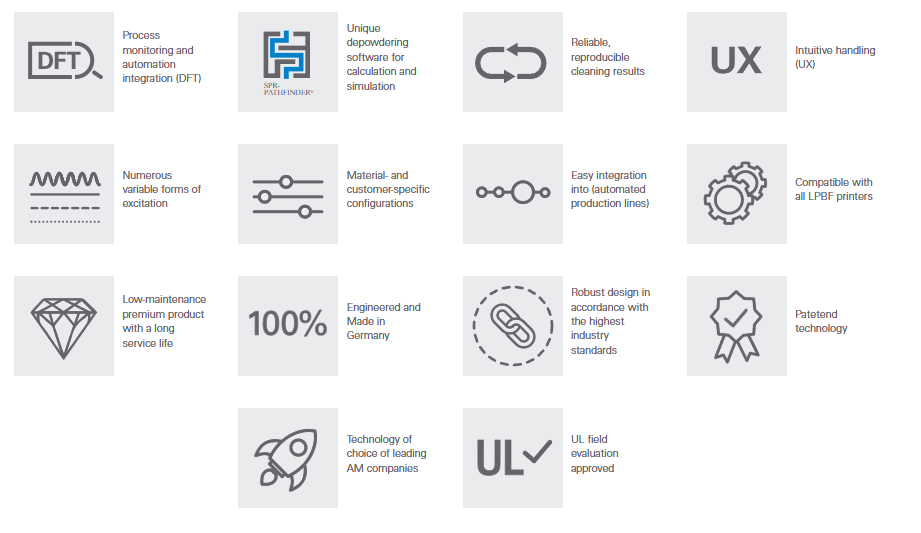

WE ARE SPECIAL AND THE ONLY ONE

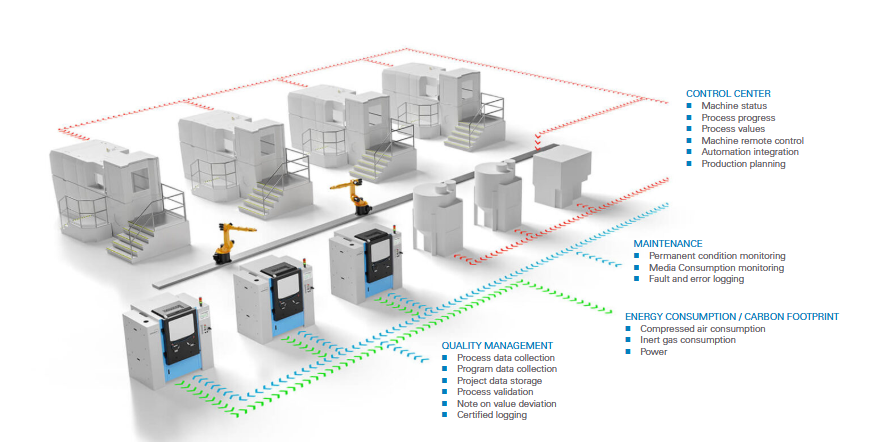

DIGITAL FACTORY TOOL

Solukon sets the standard in powder removal for metal additive manufacturing. With patented SPR® (Smart Powder Recuperation) technology, Solukon systems automate the depowdering of complex, intricate parts — enhancing safety, improving quality, and ensuring full regulatory compliance.

WE PROVIDE A BROAD LIST OF DEPOWDERING SOLUTIONS

SFM-AT 1500-S

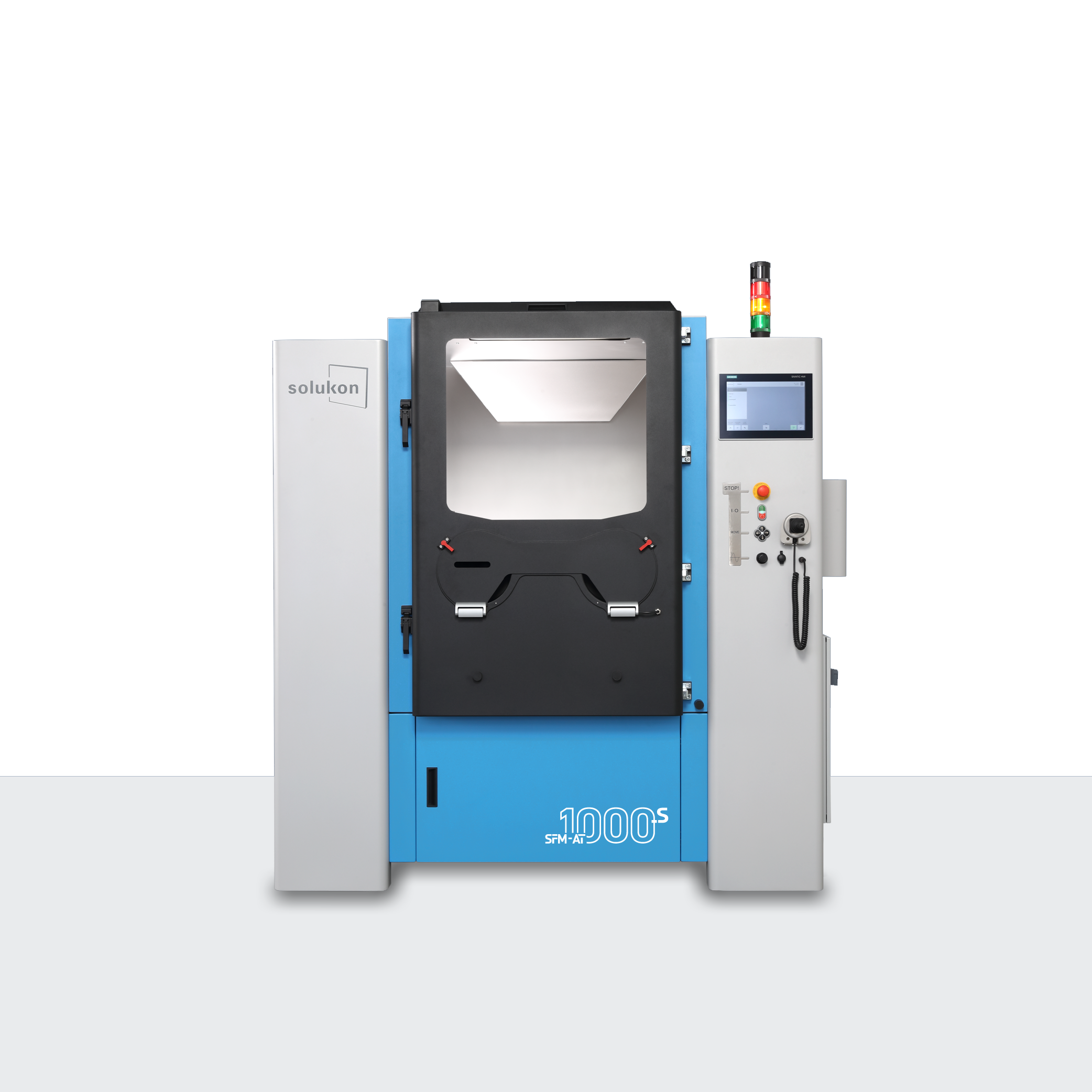

SFM-AT 1000-S

SFM-AT 800-S

SFM-AT350/E

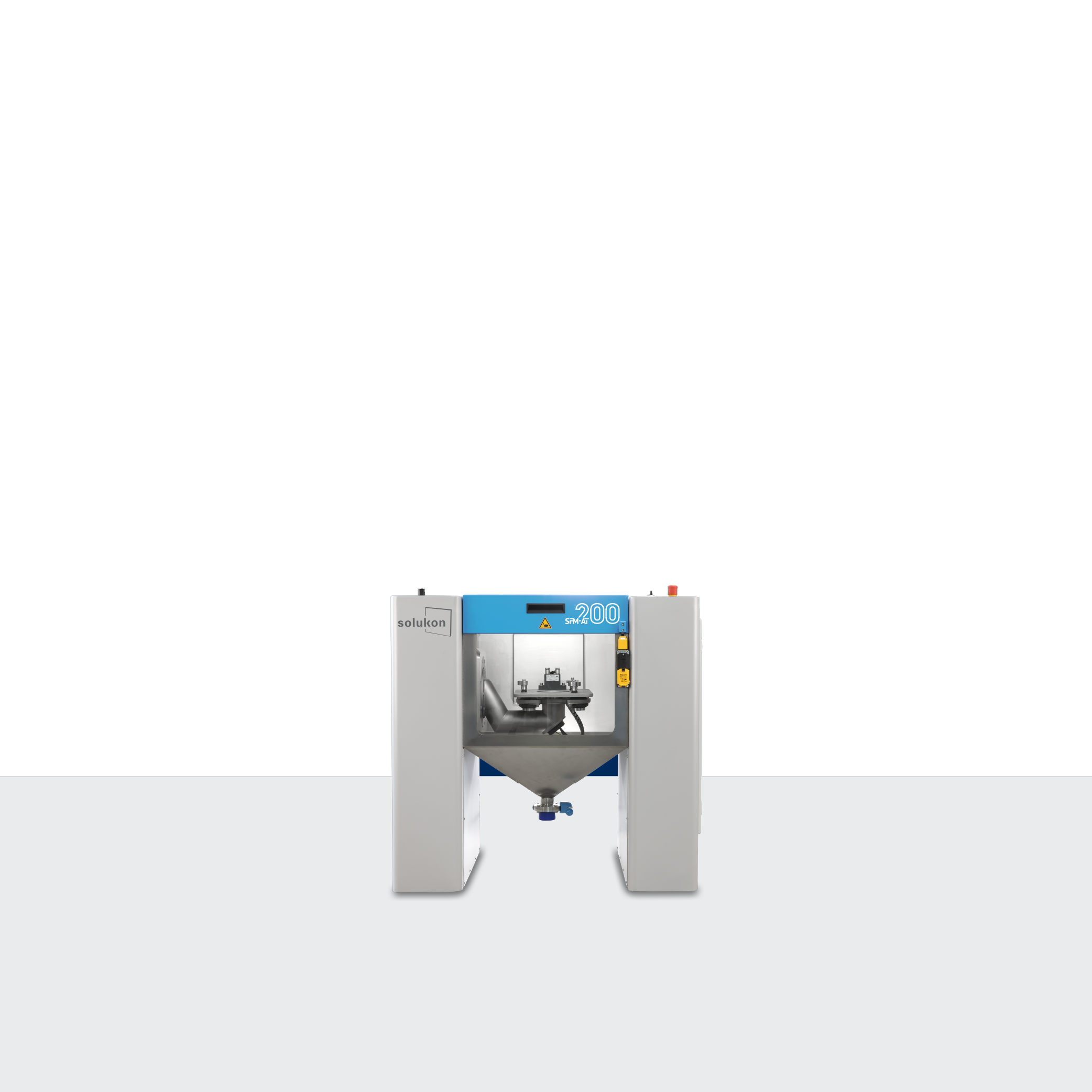

SFM-AT200

PCU

PATHFINDER

DIGITAL FACTORY TOOL

CUSTOMER INQUIRIES

PLEASE FEEL FREE TO INQUIRE ABOUT ANY ADDITIONAL QUESTIONS YOU HAVE REGARDING ROBOTICS 3D PRINTING OR METAL POWDER REMOVAL.