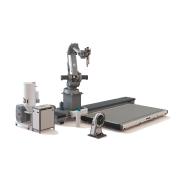

MX3D

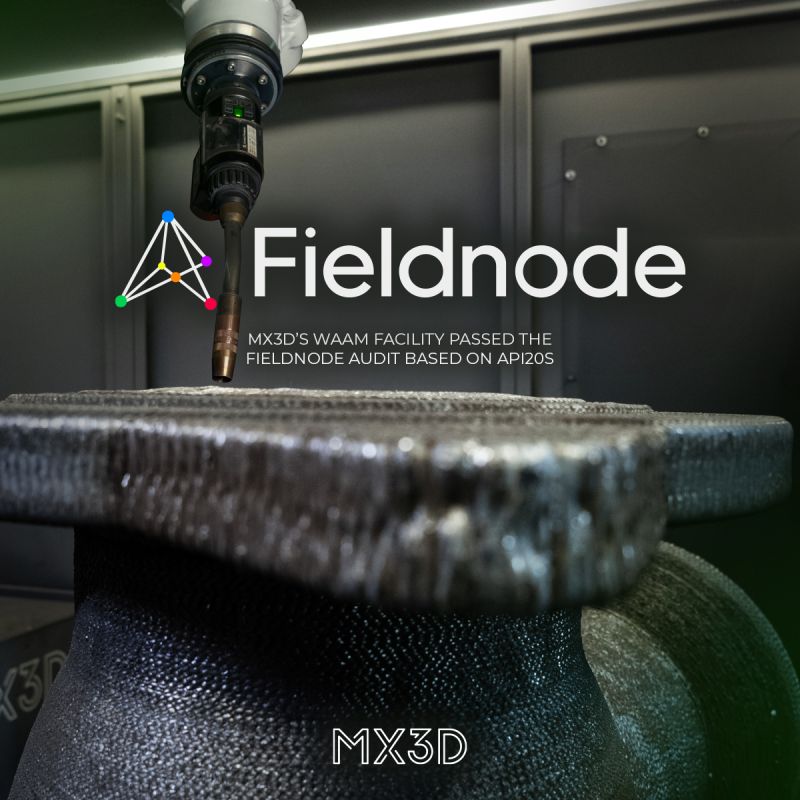

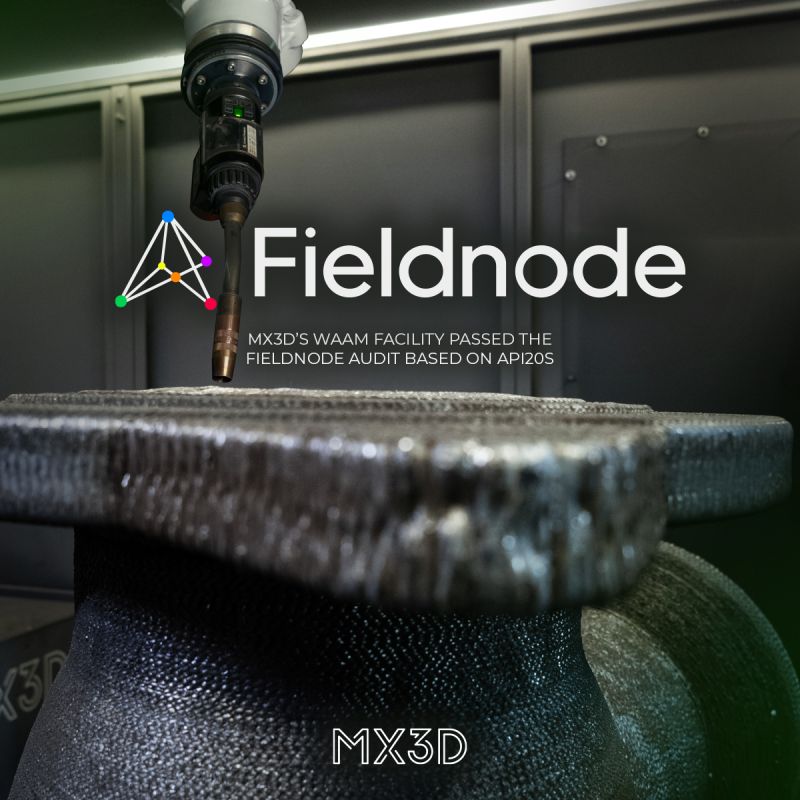

MX3D Passes Fieldnode Audit Based on API20S

We’re thrilled to announce that MX3D’s robotic WAAM facility has officially passed the Fieldnode audit based on API 20S—an achievement that marks a major milestone for HDC as MX3D’s exclusive distributor in South Korea and Japan.

Why this matters: Fieldnode is the oil & gas industry’s leading qualification platform for additive manufacturing. Its rigorous API 20S-based audit examines every aspect of a supplier’s operations—from material traceability and process control to quality assurance and safety protocols. By earning Fieldnode certification, MX3D proves that its Controlled Industrial WAAM solutions meet the exacting standards required for critical metal parts in upstream, mid-stream, and downstream applications.

What this means for our customers:

-

Guaranteed Compliance: Your parts will be produced under a fully audited, API-compliant system—eliminating uncertainty when specifying components for pressure vessels, subsea equipment, or high-temperature environments.

-

Unmatched Reliability: We know that every weld bead, every layer, and every heat treatment is traceable and validated. That translates into confidence in component performance under the most demanding conditions.

-

Faster Time-to-Market: WAAM’s near-net-shape capabilities, combined with a certified process, let you iterate designs rapidly and reduce machining steps—so critical spares and bespoke components can be delivered on-demand, without lengthy qualification delays.

At HDC, we’ve seen firsthand how MX3D’s WAAM platform transforms complex manufacturing challenges into new opportunities: large structural parts printed with minimal scrap, multi-alloy builds in a single setup, and truly digital traceability from design to delivery. Passing the Fieldnode audit simply affirms what we already believed—that MX3D’s WAAM technology is not just cutting-edge, but also rigorously proven for the oil & gas platforms, pipelines, and refineries that depend on pinpoint accuracy and uncompromising quality.